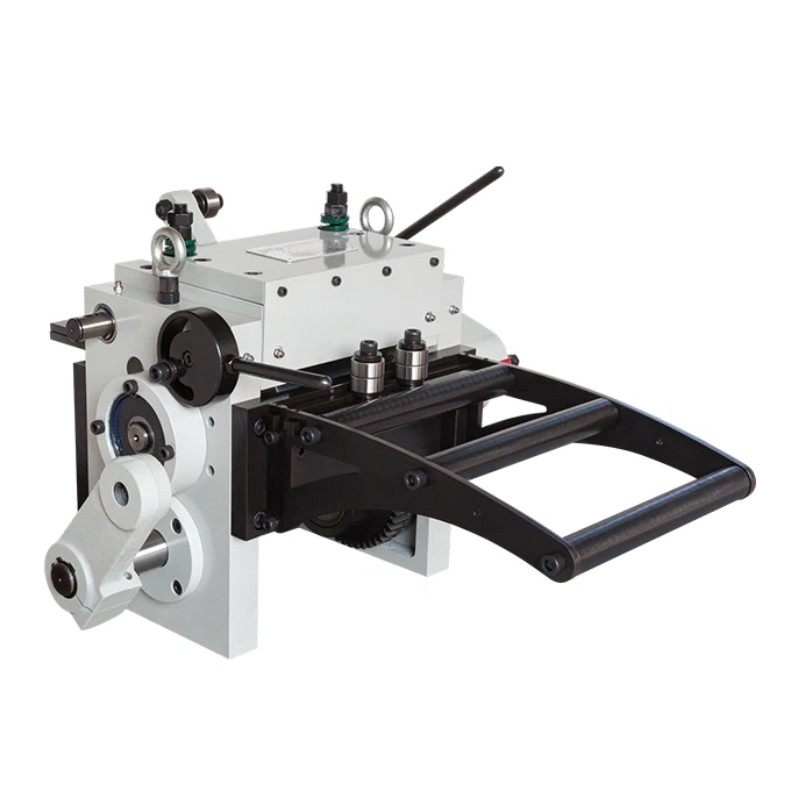

Press Feeder

The coil feeder is the "best value in the industry" because to the feed head's accurate construction and robust design. Our Coil feeders, which are based on a modular architecture, offer simple maintenance and the adaptability to rearrange machine choices should a customer's demands alter.

11 results

ViewShowcase

As one type press feeder, the High Speed Mechanical Roll Feeder is a specialized feeder for high-speed stamping lines.

As a type coil feeding equipment, the Mechanical Roll Feeder is a specialized press feeder for high-speed stamping lines.

As one type steel coil feeding machine, the Mechanical Roll Feeder is a specialized press feeder.

As one type punch press feeder, the High Speed Mechanical Roll Feeder is a specialized stamping feeder.

A Mechanical Roll Feeder is a type of the High Speed Roll Press Feeders which is a specialized press feeder.

The Coil Feeder Equipment is a press feeder designed for handling steel coils with a thickness ranging from 0.6mm to 6.0mm

The Servo Feeder Machine is a coil feeder for handling steel coils with a thickness ranging from 0.5mm to 4.5mm.

the Precision Zigzag Servo Feeder Machine is a specialized coil feeder designed for circle stamping blanking lines

The Precise Mechanical Gripper Feeder is a specialized coil feeder designed for high-speed stamping lines

As press feeder, this type coil feeder is designed for terminal, metal button, clip etc production line.

As one type of Press feeder, the NC Servo Feeder Equipment is a precision coil feeder designed for coil feeding in press line.

What Is The Function of A Coil Feeder?

A coil feeder is a specialized industrial coil handling equipment used to precisely and continuously feed coils of material, such as metal, into production processes. It ensures a consistent and controlled supply of material, enhancing production efficiency and reducing errors. Coil feeder is designed to handle a wide range of coil sizes and materials, and they often work in conjunction with other machinery like decoiler machine and straighteners. Equipped with advanced automation features, including servo-driven mechanisms and adjustable speed controls, press feeder ensures accurate and smooth material feeding, making them essential components in industries like automotive manufacturing, metal stamping, and fabrication.

Discover our range of steel Coil feeder designed to optimize material handling in various industries. Our steel press feeder ensures smooth and precise feeding of coils and sheets, enhancing the efficiency and accuracy of your production processes. Choose from different types, including NC servo feeders, roller feeders, gripper feeders, and zigzag feeders, each catering to specific material handling needs. Explore our solutions today for improved productivity and streamlined operations.

Subtypes Within The Coil Feeder Group

These cutting-edge feeders utilize advanced servo technology to provide precise and synchronized material feeding. They are the ideal choice for industries that demand intricate part production with minimal tolerances.

Designed for versatility, roller feeders ensure smooth and consistent material advancement. Their roller-based design reduces friction, making them suitable for a wide range of materials.

Engineered to handle complex shapes, gripper feeders offer reliable feeding of irregular materials. They are especially valuable in applications requiring precision, such as intricate metal forming.

Perfect for high-speed operations, zigzag feeders offer rapid and controlled material advancement. They play a pivotal role in industries with demanding production schedules.

Frequently Asked Questions

Q1: What is a press feeder used for?

A1: A press feeder is a steel coil handling equipment used to automate the feeding of coil materials, such as metal sheets or strips, into various production processes, including stamping, forming, and punching.

Q2: What are the types of press feeders available?

A2: There are several types of press feeders, including NC servo feeders, roller feeders, gripper feeders, and zigzag feeders, each designed to suit different material handling requirements.

Q3: How does an NC servo feeder work?

A3: An NC servo feeder uses precision servos and advanced controls to accurately feed materials at a programmed length and speed. This type of feeder is suitable for high-speed and high-precision applications.

Q4: What are the benefits of using a roller feeder?

A4: Roller feeders use sets of rollers to guide and feed materials. They are known for their versatility, handling a wide range of materials and thicknesses with ease, making them suitable for various industries.

Q5: What is the function of a gripper feeder?

A5: A gripper feeder employs mechanical grippers to firmly hold and advance materials. This type of feeder is ideal for materials with irregular shapes or when precise feeding accuracy is required.

Q6: How does a zigzag feeder work?

A6: Zigzag feeders use a unique zigzag pattern to feed materials. This design minimizes the risk of material slippage and ensures consistent feeding, making it suitable for delicate or slippery materials.

Case Studies

Discover how our steel press feeders have transformed industries:

subscription

Or send us messages online !

- *Phone

- *Title

- *Content