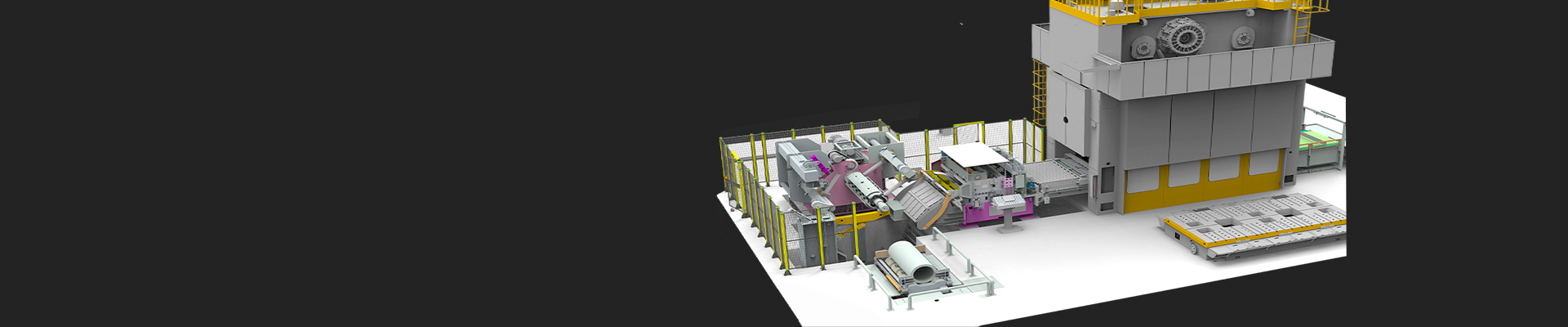

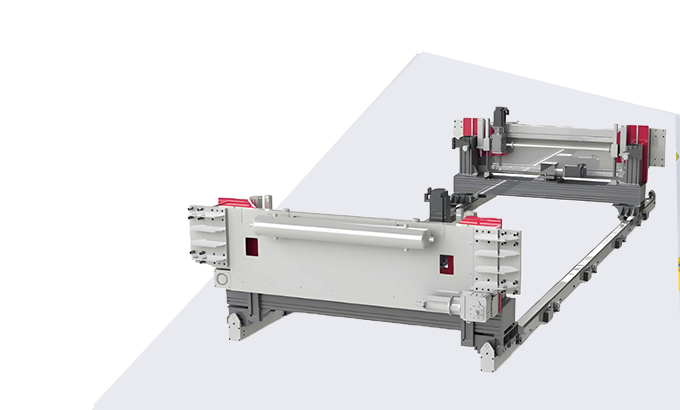

High Speed Punch Press Stamping Line

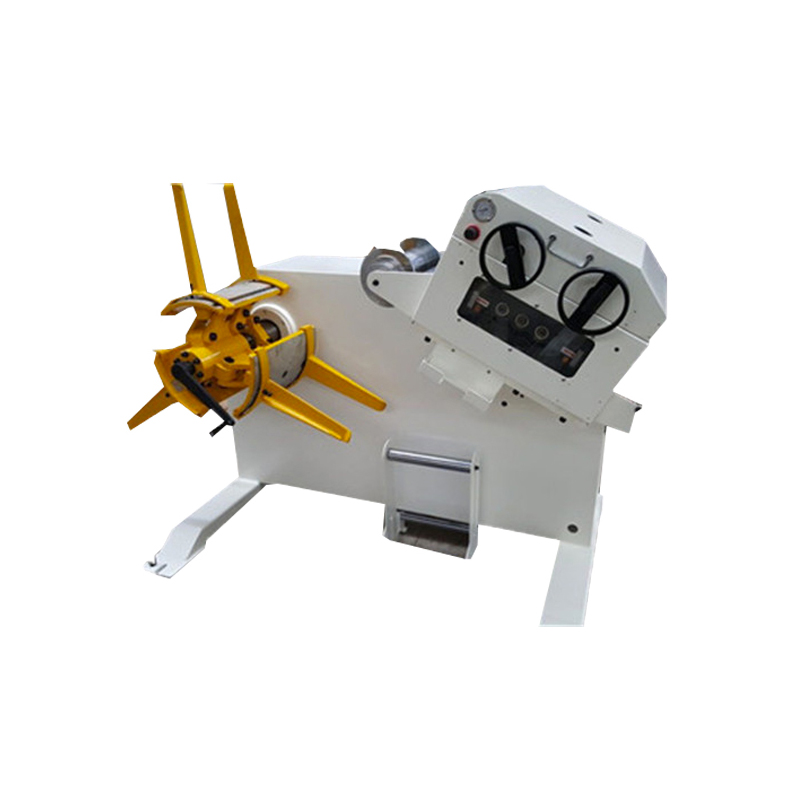

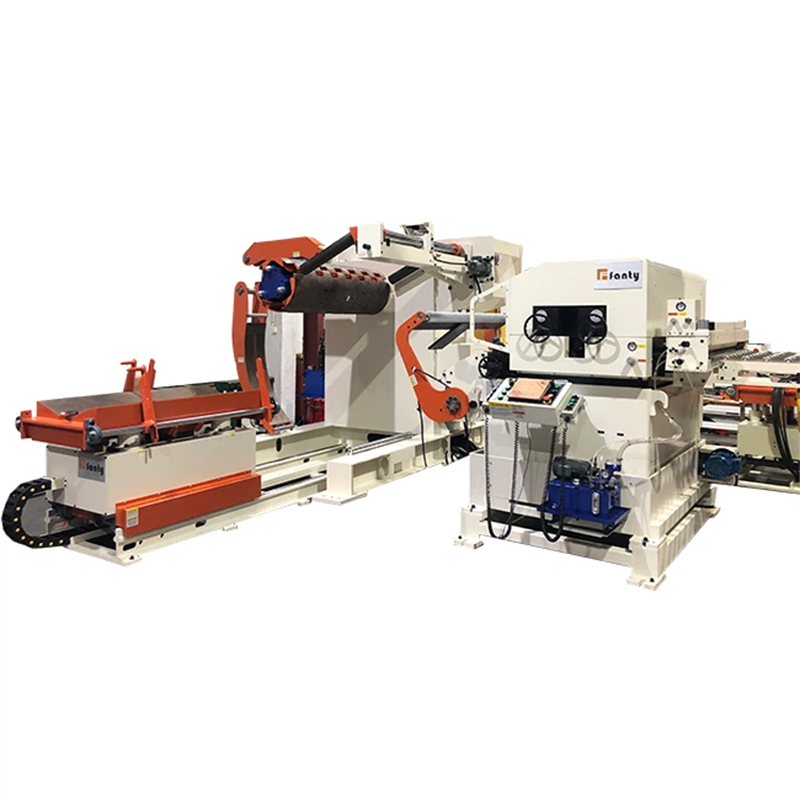

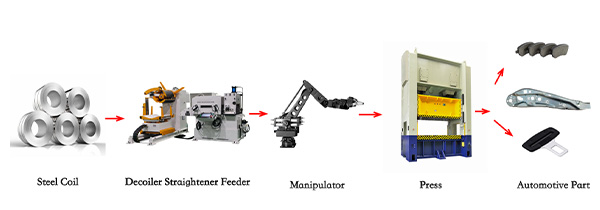

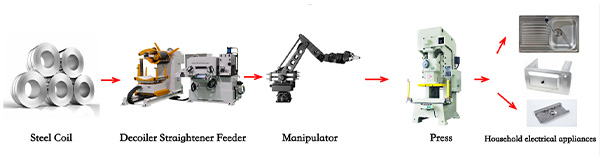

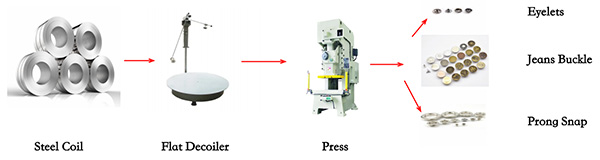

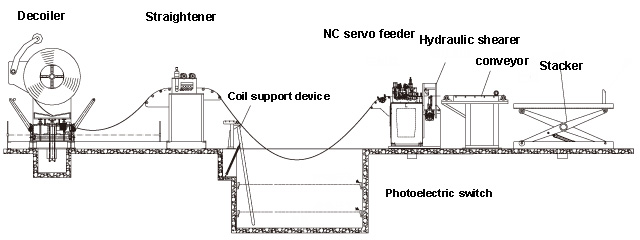

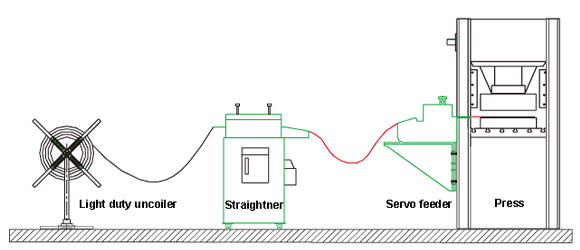

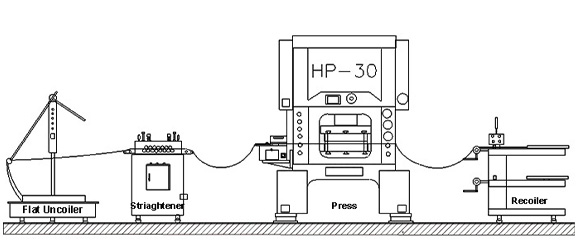

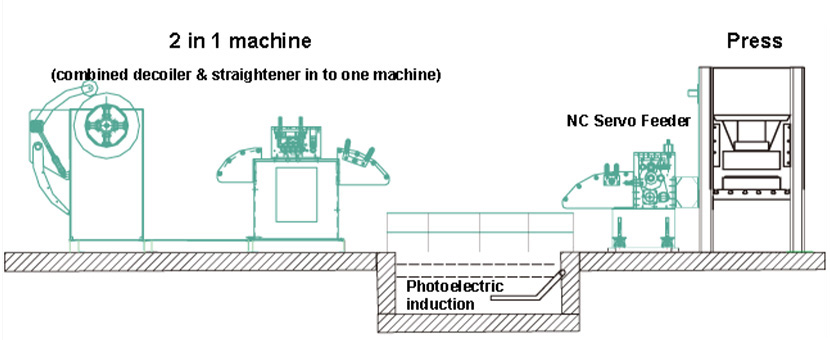

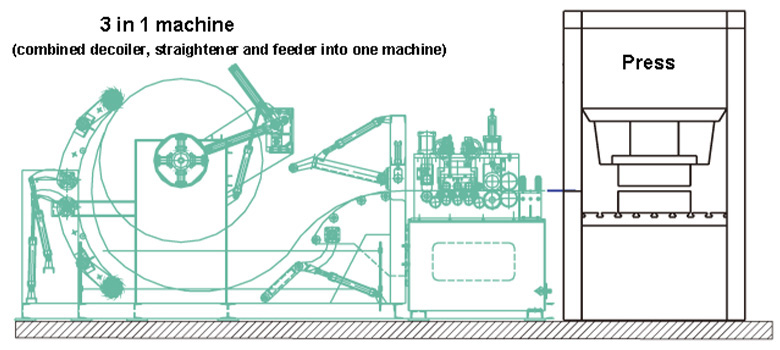

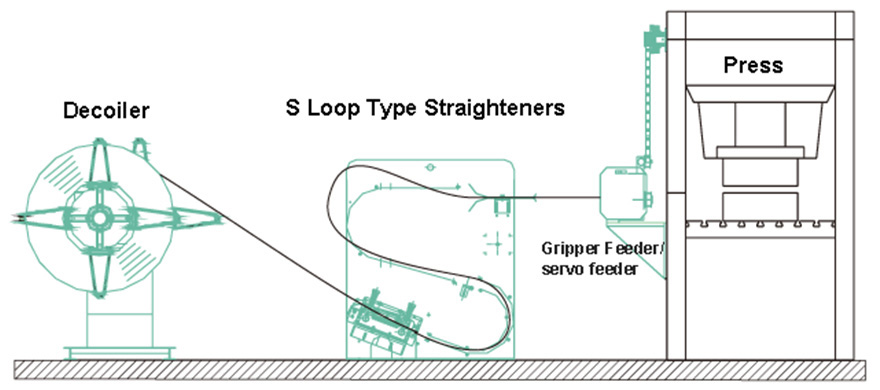

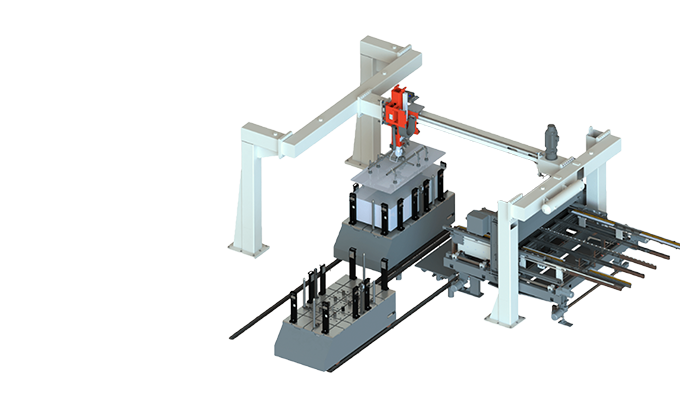

A high-speed coil feeding line system offers several advantages over traditional gear feeding systems. These include higher speed, greater precision, increased automation, space efficiency, and flexibility. High-speed coil feeding lines can handle a wider range of materials, operate with minimal human intervention, and are more compact, making them a more efficient and effective choice for production facilities. Ultimately, these benefits can lead to increased output, improved product quality, and a safer workplace.High-speed stamping lines are typically used to produce metal parts such as brackets, clips, connectors, contacts, and terminals, which are used in a wide range of applications. The automotive industry, for example, uses high-speed stamping lines to produce metal parts such as engine components, suspension components, and body parts.