Company News

Fanty News

- Wish Our Amazing Customers Merry ChristmasA Heartfelt Holiday Wish to Our Amazing CustomersDec 22,2025

- Never Forget History, Strive for Strength: 94th Anniversary of the Mukden IncidentNever forget history, strive for strength. On September 18, 2025, we commemorate the 94th anniversary of the Mukden Incident with the latest news and events.Sep 18,2025

- Fanty Brings New Coil Processing Equipment for Romanian PartnerLearn how Fanty Machinery installed the MT-500 Decoiler, Straightener, and NC Servo Feeder for a Romanian client, enhancing two coil feeding lines with top-tier automation.Sep 2,2025

- Fanty Completes MT-500 Hydraulic Decoiler for Romania ClientDiscover how Fanty successfully manufactured the MT-500 Hydraulic Decoiler for a Romania client, enhancing coil feeding line efficiency. Learn more!Aug 11,2025

- Fanty Ships Two APA-60 Punch Press Machines to Czech Republic for Precision StampingFanty has completed shipment preparations for two APA-60 punch press machines bound for the Czech Republic.Jul 1,2025

- Fanty Ships Coil Feeding Line Solution to Czech Republic: 3 Sets of GL-300 + NCF-300 MachinesFanty has successfully delivered a complete coil feeding line solution to a customer in the Czech Republic, including 3 sets of GL-300 decoilers and 3 sets of NCF-300 servo feeders.Jun 18,2025

- FANTY 2025 Dragon Boat Festival Holiday NoticeFANTY announces a 3-day holiday from May 31 to June 2 (resuming June 3), aligned with national guidelines for a 2025 The Dragon Boat Festival.May 30,2025

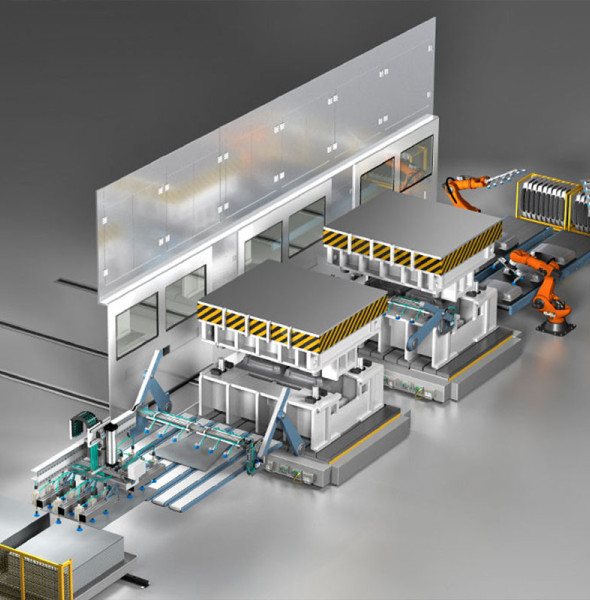

- What Is the Role of Coil Processing Equipment in Automotive Metal Stamping ?In the automotive metal stamping industry, coil handling equipment plays a pivotal role in manufacturing various automotive components, from body panels to structural parts.Apr 30,2025

- How to Mast the Purchase of Decoiler Straightener Feeder for A Shelving Production in 2025 ?In the high-quality shelving manufacturing, Decoiler Straightener Feeder is important. Sure, the machine purchase decision is important also in 2025. Let's explore more from multiple perspectives.Apr 24,2025

- How Are Smart Decoilers Enhancing Automation in Metal Stamping?Smart decoilers with servo control, IoT monitoring, &automated coil handling are enhancing metal stamping in 2025.Mar 4,2025

- What Are the Latest Innovations in Coil Feed Lines for the Automotive Industry?Explore the latest innovations in coil feed lines, including servo-driven coil feeders systems, IoT monitoring, and energy-efficient solutionsFeb 28,2025

- How Can Coil Feed Lines Enhance Efficiency in Stamping Processes in 2025?Coil feed lines optimize stamping processes by improving material flow, reducing waste, and minimizing downtime in 2025.Feb 27,2025

News Group

Are you looking for a reliable manufacturer of coil processing equipment?

We can quickly quote it for customers with timely response, technical support and customized services.subscription

Or send us messages online !

- *Mobile Phone

- *Title

- *Content