What are the issues preventing the uncoiler machine from turning on?

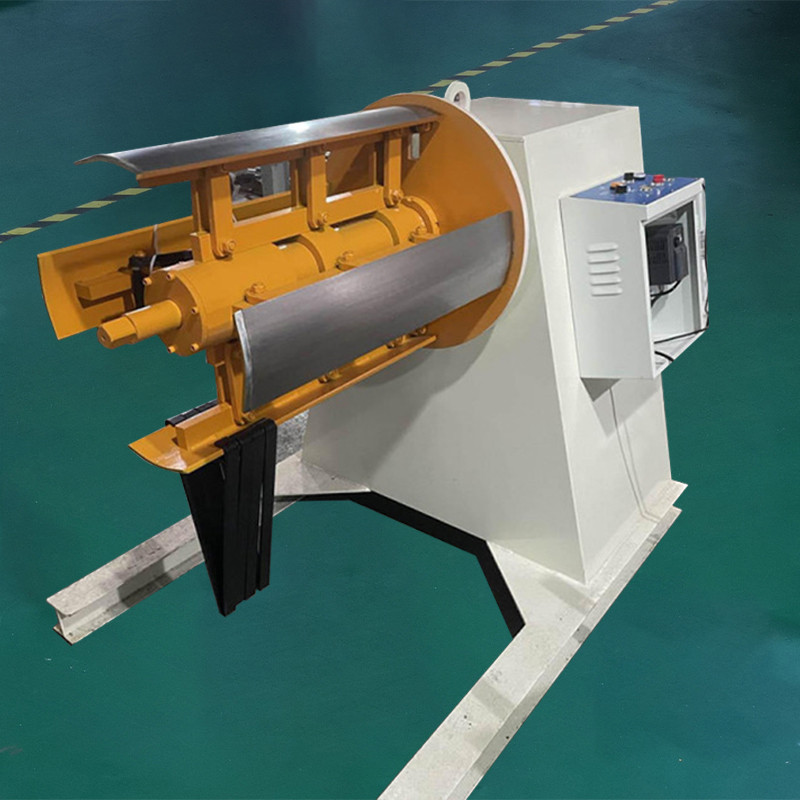

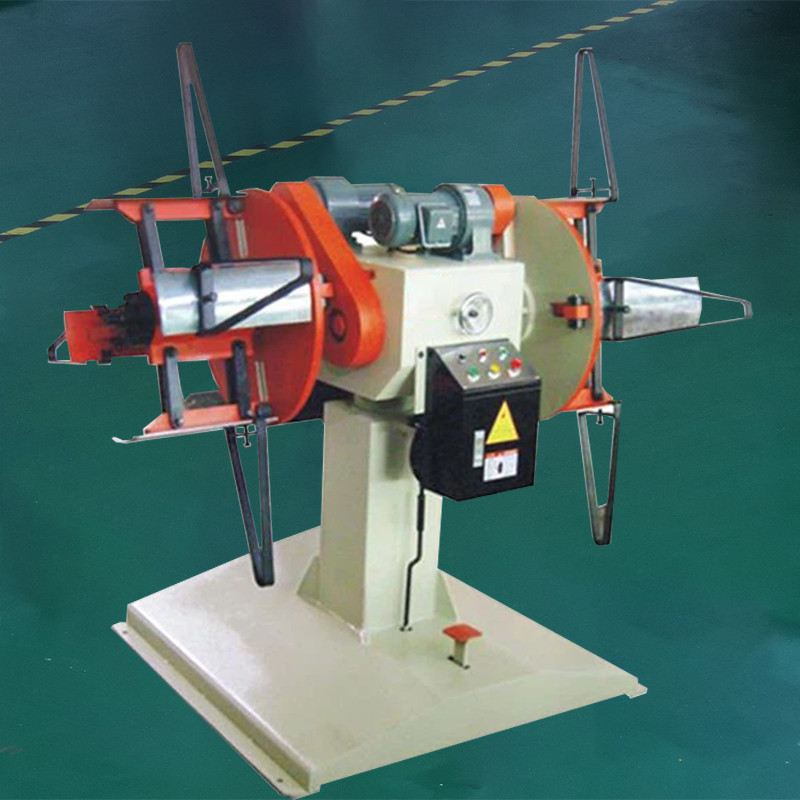

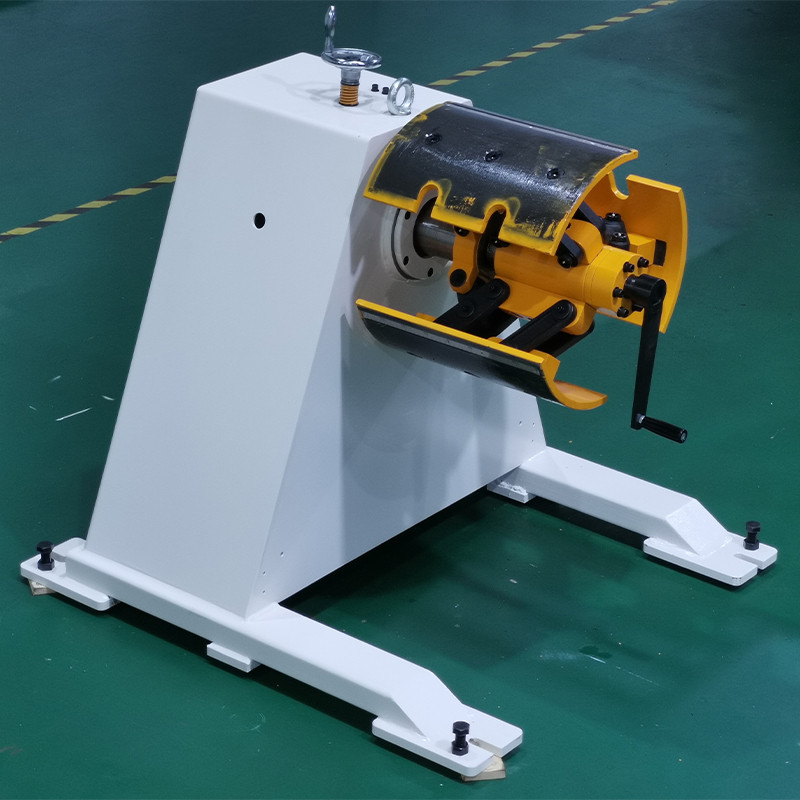

Decoiler is a type of steel coil handle equipment. It is also called Uncoiler. An increasing number of customers are choosing the uncoiler due to its excellent stability and low failure rate. Naturally, maintenance on the device must also be taken care of, regardless of how well the uncoiler performs when in use. Failures are inevitable as soon as maintenance is neglected. The processing and output of the entire automated manufacturing line will be directly impacted if the defect cannot be fixed and the uncoiler cannot be utilized regularly. Learn more about decoiler here.

When switching out different materials for the uncoiler, a common uncoiler malfunction is its inability to start automatically. Currently, there are often five causes, and once they are identified, they can be resolved by taking each one out one at a time.

1. The uncoiler fails to start normally because the time relay in the electric control box on the side of the unit has an excessively lengthy delayed start time. Materials must be adjusted in accordance with actual processing and production needs since they differ in thickness, stamping processing speed, and time relay adjustment delay start times.

2. The uncoiler is not starting normally because the wire that connects it to the induction rod is either broken or has inadequate contact. After inspecting the line that connects the induction rod, the problem can be resolved.

3. The failure to start normally is caused by damage to the transformer, AC contactor, time relay, and intermediate relay in the electric control box on the side of the uncoiler. Electrical experts must inspect the electrical parts of the uncoiler control box for damage and replace any that are found to be damaged.

4. The inability to drive is caused by either the shaft pin card connecting the motor and reducer falling off or the motor drive belt in the uncoiler box coming off. Once the uncoiler's power connection line has been removed, take out the four screws on the back and inspect the shaft pin card and transmission belt.

5. The uncoiler box's motor is damaged, making it unable to operate. There is little chance that this will go wrong. This inspection is done after the four objects listed above have been removed.

You can also get in touch with us directly if the uncoiler won't start, and we'll assist you in fixing the issue.

Please click the following article to learn more about the uncoiler.

What Uncoiler/Decoiler Does FANTY Manufacture?

If you have any other question or inquiry, pls contact us fanty@sz-fanty.com.