What Is the Future of Zigzag Feeders in Flexible Manufacturing in 2026?

What Is the Future of Zigzag Feeders in Flexible Manufacturing in 2026?

Posted on Jan 29, 2026 | By Sophia Lin, Advanced Feeding Systems Engineer at Fanty Machinery

Material utilization has become the #1 profit lever in flexible manufacturing. With steel and aluminum prices volatile and EV/electronics parts demanding ever-more complex shapes, the ability to nest parts tightly across wide coils is no longer nice-to-have—it's survival. In 2026, zigzag feeders are evolving from niche tools into core enablers of smart, low-waste production. Having designed and deployed zigzag systems for over 120 factories in the past four years, I've seen material savings jump from 8–12% to 28–44% when the right technology meets the right strategy. If you're still running straight-line feeding in progressive or transfer dies, you're almost certainly leaving 15–35% of your coil value on the scrap pile. Here's what the leading edge looks like right now—and why 2026 is the year to act.

1. AI-Optimized Zigzag Paths — 35–44% Material Savings Become Standard

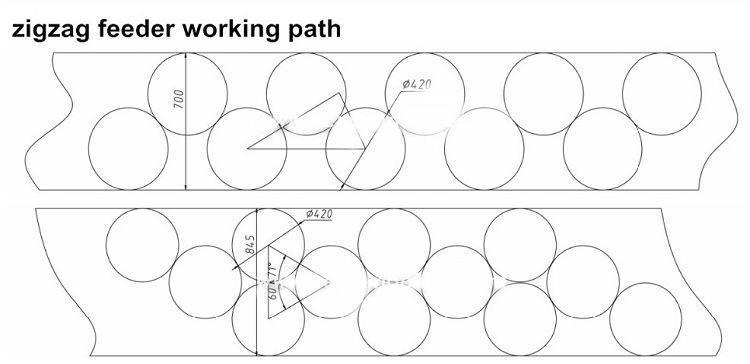

2026 zigzag feeders no longer rely on fixed offset patterns. Onboard AI and cloud-connected nesting engines analyze part geometry, coil width, grain direction constraints and even upcoming orders in real time, generating dynamic zigzag paths that maximize utilization. We've documented runs hitting 41–44% savings on asymmetrical brackets and multi-cavity dies—savings that were considered "impossible" just two years ago. For a mid-size automotive stamper we equipped in Q4 2025, this translated to $420,000 in annual material cost reduction on a single line.

2. Lightning-Fast Pattern Switching — True High-Mix Flexibility

Flexible manufacturing means changeovers every 1–4 hours, not every shift. Modern zigzag systems now switch nesting patterns in under 45 seconds via touchscreen or MES command—no mechanical adjustments needed. Servo-driven X-axis traverses at 1.5–2.5 m/s with ±0.05 mm repeatability, allowing you to run family-of-parts dies or mixed batches without stopping the press. Clients running 8–12 different SKUs per day report overall equipment effectiveness (OEE) climbing from 68% to 89% after adding this capability.

3. Multi-Material & Thickness Switching Without Re-Calibration

The future is mixed-material lines—AHSS one hour, aluminum the next, different gauges within the same family. 2026 zigzag feeders feature auto material detection (via laser or camera) and instant parameter recall from a cloud library. No more 15–30 minute re-teach for each coil change. In a European white-goods plant we supported, this eliminated 90% of changeover scrap and allowed true one-piece-flow across four different material types per shift.

4. Integration with MES & Digital Twin for True Smart Manufacturing

Zigzag feeders in 2026 are no longer standalone. Full OPC UA / Ethernet/IP integration feeds real-time coil usage data into MES and digital twin platforms. You can simulate next week's material consumption, predict coil change timing, and even auto-order coils based on nesting efficiency forecasts. Early adopters are seeing 12–18% additional savings through better planning and inventory reduction alone.

Why Forward-Thinking Manufacturers Are Choosing Fanty Zigzag Feeders in 2026

Fanty Machinery has been at the forefront of zigzag feeding technology since 2018. From our 45,000 m² facility in Dongguan, our 370-person team—including 80 R&D engineers—has delivered zigzag-capable servo feeders to over 2,000 production lines worldwide, including major automotive, appliance and electronics manufacturers such as BYD. Every Fanty zigzag feeder includes:

- AI path optimization engine (cloud + onboard hybrid)

- 1.5–2.5 m/s traverse speed with ±0.05 mm repeatability

- Instant pattern switching (<45 s) via MES or touchscreen

- Auto material/thickness detection & parameter recall

- Full OPC UA integration & digital twin compatibility

- CE certified with 36-month servo warranty

Q1 2026 Zigzag Promotion: FREE Material Utilization Audit (includes coil nesting simulation & projected savings report) + 12% discount on orders placed before March 31 + FREE on-site pattern optimization session.

Claim FREE Utilization Audit & Quote →

Response within 24 hours • Confidential • No obligation

Quick Zigzag Readiness Self-Check

- Material utilization below 75–78% on wide coils?

- Frequent coil changes or mixed-material runs?

- Scrap from poor nesting >8–10%?

- Want to run more complex or asymmetrical parts?

- Pressure to reduce material costs by 15–25% in 2026?

If you answered YES to 3 or more — a modern zigzag feeder upgrade will likely deliver ROI in < 9 months. Let's calculate your exact potential together.