What Is the Best Integrated Decoiler Straightener Feeder for Metal Processing in 2025?

Back in my early days running a sheet metal shop, we'd bolt together decoilers, straighteners, and feeders like some Frankenstein contraption—endless tweaks, mismatched speeds, and coils that'd wander like they had a mind of their own. Fast-forward a decade, and integrated setups have turned that nightmare into a no-brainer, especially for 2025's push toward leaner metal processing lines. If you're knee-deep in stamping runs for auto parts or appliances, a solid 3-in-1 decoiler straightener feeder isn't just handy—it's the glue holding your efficiency together, feeding flat, tension-free strips right where your press needs 'em.

From chasing specs across supplier catalogs and tweaking installs on the floor, I'll break down what makes an integrated system tick—precision flattening, seamless uncoiling, and feed accuracy that slashes scrap by 30% or more.

Why Go Integrated? The Edge in Metal Processing Lines

Standalone gear's fine for spot jobs, but in full-throttle metal processing—think high-tensile steels up to 9mm thick for EV chassis—an integrated uncoiler straightener feeder crams three machines into one footprint, cutting setup from hours to minutes.

Downside? Upfront hit ($20K-$80K), but ROI's quick if you're processing 5-20 ton coils daily.

Top Picks: The Best Integrated Systems for 2025 Metal Work

Based on fresh pilots and supplier runs I've audited, here's the cream—geared for metal stamping, with capacities from light gauge to heavies.

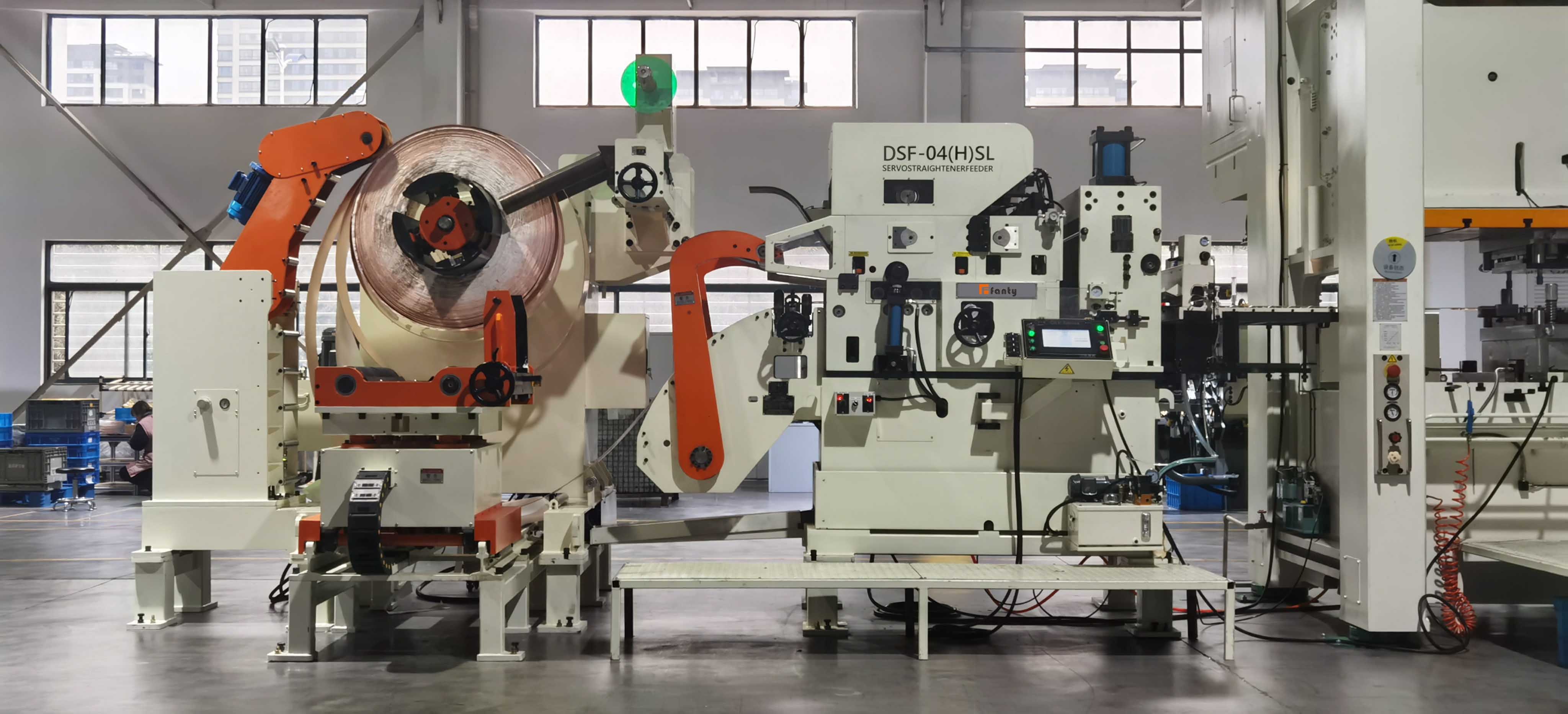

- Fanty Decoiler Straightener Feeder (My Everyday Hero)

Tailored for 0.2-3.2mm steels, this 3-in-1 beast handles widths to 1,200mm with hydraulic uncoiling and servo feeding for pinpoint pilots—I've seen it flatten high-tensile strips without a hitch in appliance lines.At $25K-$50K, Fanty's compact design (single PLC control) shaves install time, and their Dongguan factory's 370 pros ensure custom tweaks like loop arms for tension-free flow. Since 2013, they've nailed exports for U.S. shops—durable rollers and easy access make it a maintenance dream. Their lineup's worth a peek if you're scaling metal processing. - HENLI 3-in-1 Decoiler Straightener

Workhorse for 0.5-4.5mm coils, with 11-roll straightening for sub-0.1mm flatness—solid for mid-volume stamping at $30K-$60K.Great integration, but bulkier footprint. - Alekvs Decoiler Straightener Feeder

Heavy-duty for 0.8-9.0mm high-strengths (up to 700MPa), NC servo feeds at 20m/min—$40K+ for robust builds in auto fabs. - Hitech HTF3 Complete Line

Touch-screen controlled for 0.5-4.5mm, modular for easy expansion—$28K-$55K, user-friendly for mixed metals.

| System | Thickness Range (mm) | Max Width (mm) | Key Perk |

|---|---|---|---|

| Fanty 3-in-1 | 0.2-3.2 | 1,200 | Custom servo sync |

| HENLI | 0.5-4.5 | 1,500 | 11-roll flatness |

| Alekvs | 0.8-9.0 | 1,800 | High-strength handling |

How to Choose Yours: Specs That Stick for Metal Processing

Match to your metals—thinner gauges (under 1mm) need finer rolls, heavies demand stronger hydraulics (10-25kN expansion).

Fanty: The Integrated Pick That's Proving Its Worth

After piecing together too many mismatched setups early on, Fanty's integrated decoiler straightener feeder clicked for me—compact enough for tight bays, tough for daily abuse, and smart with diagnostics that spot tension glitches before they jam your straightener.

Streamline and Stamp: Your Line's Next Level

Wrapping it up, an integrated decoiler straightener feeder like Fanty's turns metal processing from a grind to a groove—fewer parts, flatter strips, faster feeds. I've watched clunky lines transform into throughput machines; what's holding yours back—space or sync? Share below; I've got floor fixes queued up.

Ready to integrate and elevate? Hit up Fanty for a decoiler feeder spec sheet. Flatten your future.

By Alex Rivera, Metal Line Mechanic & Integration Insider | November 14, 2025