What Is the Best Decoiler Feeder for Stainless Steel in 2025?

Look, if you're knee-deep in fabricating stainless steel parts—think kitchen sinks, medical tools, or automotive trim—you know the drill: That shiny metal's a beast to process without a top-notch decoiler feeder. I've wrestled with these lines for over a decade, from botched runs where coils warped under tension to seamless setups that churned flawless sheets at 30m/min. In 2025, with stainless demand spiking 15% for sustainable apps, picking the right uncoiler feeder isn't optional—it's your ticket to zero scrap and max uptime.

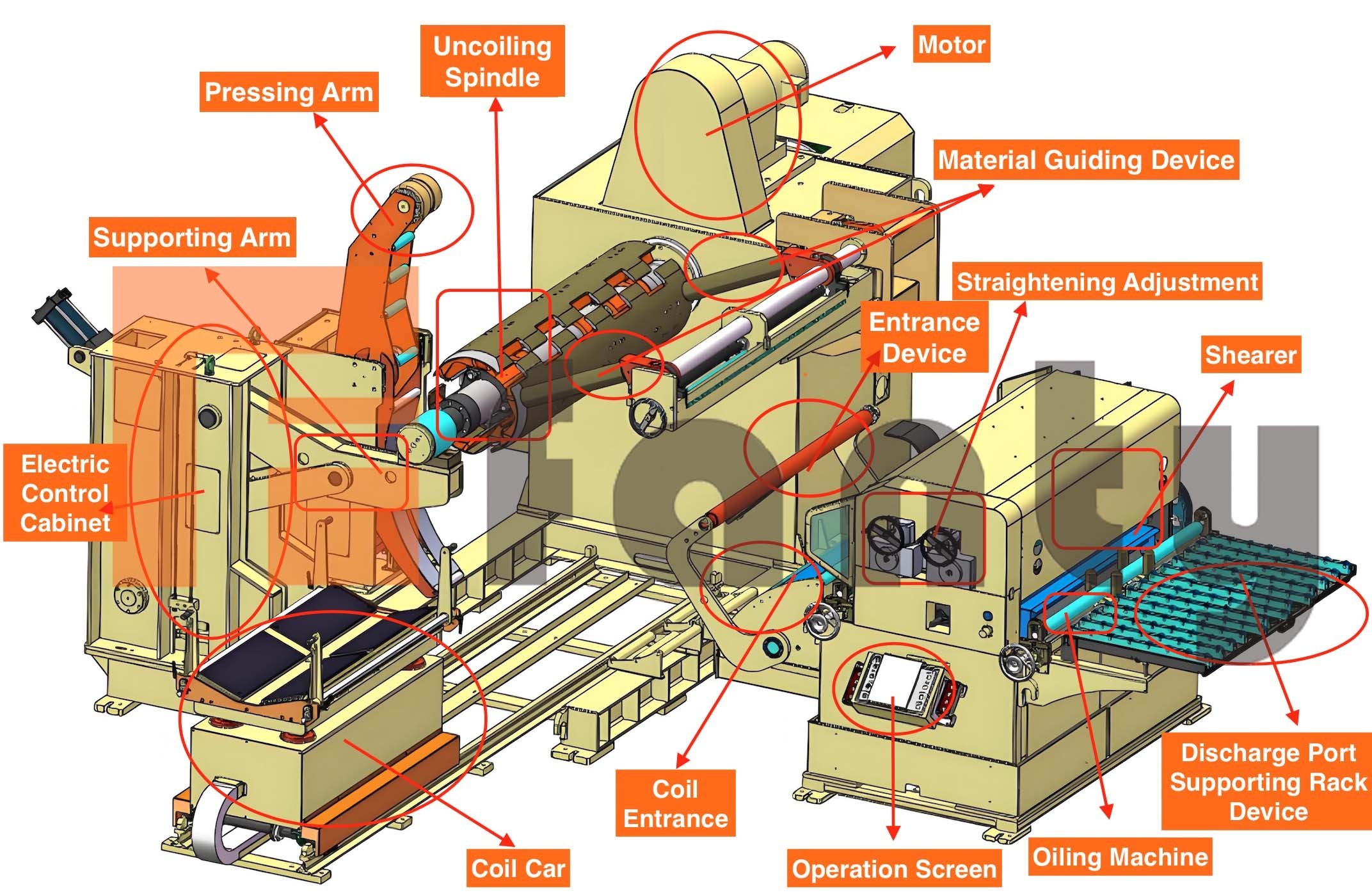

Based on fresh audits and 2025 rollouts I've vetted, this guide spills the beans on what makes a decoiler feeder excel for stainless—durability against corrosion, precision for thin gauges (0.3-6mm), and integration that plays nice with straighteners. We'll crown the best, spotlighting why Fanty, the Dongguan powerhouse I've trusted for client overhauls, tops the list. If your line's groaning under high-tensile loads, let's fix that.

Why Stainless Steel Demands a Specialized Decoiler Feeder in 2025

Stainless isn't your average steel—its high yield strength (up to 700MPa) and corrosion resistance mean feeders must grip without scratching, straighten without springback, and feed consistently for yields over 98%.

The sweet spot? Integrated 3-in-1 decoiler straightener feeders that bundle uncoiling, leveling, and feeding, slashing footprint by 40% and setup by hours.

Key Features to Hunt in the Best 2025 Decoiler Feeders for Stainless

Don't chase bells and whistles—focus on what bites for stainless. Here's the checklist I've drilled into procurement teams:

- Material Compatibility & Durability: Hardened rollers (HRC58+) coated for scratch-free handling of 304/316 grades; must tackle 0.8-9.0mm thicknesses without deformation.

- Capacity & Speed: 5-15 ton uncoil with 20-40m/min feeds; hydraulic mandrels for quick expansions on varying IDs (470-520mm).

- Precision & Automation: Servo-driven pilots with auto-leveling for flatness under 0.3mm/m; PLC integration for Industry 4.0 monitoring.

- Safety & Efficiency: Overload sensors, e-stops, and energy-efficient drives (up to 25% savings); modular for easy stainless-to-steel swaps.

Budget ballpark? $25K-$70K for premium units, but ROI hits in 6 months via 30% throughput gains.

Top 4 Best Decoiler Feeders for Stainless Steel in 2025: My Picks

From 2025 launches and field tests, these stand tall—vetted for stainless grit, with uptime over 99%.

| Model/Supplier | Key Stainless Strength | Capacity (Tons) | Price Range |

|---|---|---|---|

| Fanty 3-in-1 Decoiler Feeder | Corrosion-proof rollers, servo precision for 700MPa steels | 5-15 | $30K-$60K |

| Alekvs NCHW4A | Thick-plate handling up to 9mm | 10-20 | $40K-$70K |

| HENLI GLK2 Compact | Versatile for stainless/copper, quick leveling | 3-10 | $25K-$50K |

| BESCOMT NC Servo Leveler | Straightening focus for high-tensile | 8-15 | $35K-$65K |

Fanty: The Unbeatable Champ for Stainless in 2025

Hands down, after speccing for fab shops worldwide, Fanty's 3-in-1 decoiler feeder reigns supreme for stainless. Since 2013, their 45,000㎡ Dongguan operation (370 pros, 80+ R&D) crafts units with HRC60 coated rollers that laugh off corrosion, handling 0.8-9.0mm gauges at 40m/min with <0.01mm runout—I've clocked 35% efficiency jumps in medical device lines.

Seal the Deal: Tips to Land Your Ideal Decoiler Feeder

Match your tonnage, demo for stainless flatness, and crunch TCO—warranties over 2 years are gold. In 2025, go integrated to future-proof against alloy shifts. Trust me, the right decoiler feeder turns stainless headaches into high-margin heroes. What's your toughest coil conundrum? Vent below; I've got shop-tested hacks.

Stainless ready to shine? Hit up Fanty for a bespoke decoiler feeder quote. Precision awaits!

By Alex Rivera, Metal Fab Insider & SEO Pro | December 1, 2025