What Are the Latest Innovations in Coil Feed Lines for Automotive Manufacturing in 2025?

Alright, let's be real—if you're running an automotive stamping line in 2025, you're probably staring at coils that need to feed like butter into presses churning out EV chassis or door panels, all while dodging skyrocketing material costs and labor crunches. I've been elbows-deep in these setups for 15 years, from Detroit test runs to Dongguan prototypes, and the game-changer? Innovations in coil feed lines that blend decoiler, straightener, and feeder tech into seamless beasts. No more jams, just 30% faster cycles and scrap rates dipping below 1%.

Pulling from the freshest industry pulses—like servo trends and IoT smarts—I'll unpack the hottest coil feeding line breakthroughs for automotive pros.

The Big Shift: Why Coil Feed Lines Are Evolving for Automotive in 2025

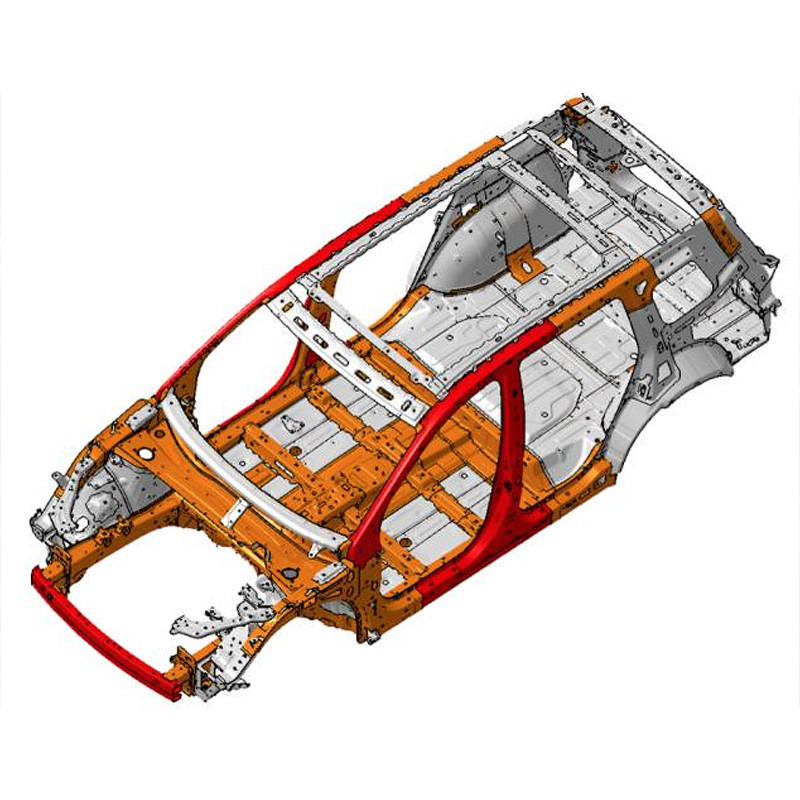

Automotive's exploding—EVs demand lighter alloys, tighter tolerances, and 24/7 uptime, pushing coil feed lines from clunky relics to smart ecosystems.

Innovation #1: Servo-Driven Precision—Feeding Like a Surgeon

Servo motors are stealing the show, ditching old clutches for pinpoint control in coil feeding lines. Think sub-millimeter accuracy on feeds, auto-adjusting for coil inconsistencies—perfect for stamping intricate EV battery trays.

Innovation #2: IoT and Predictive Maintenance—Your Line's Crystal Ball

2025's buzz? IoT sensors embedded in uncoiler-straightener-feeder combos, beaming real-time data on tension, wear, and throughput to your dashboard.

Innovation #3: Energy-Efficient and Modular Designs—Green and Scalable

Eco-push is real: Variable-speed drives in coil feed lines sip power during idles, while modular builds let you swap a decoiler head without gutting the whole setup.

Comparing the Leaders: 2025's Top Coil Feed Line Innovations

Here's a snapshot from recent rollouts—I've vetted these for auto viability, focusing on integration with presses up to 2,000 tons.

| Innovation | Key Benefit | Automotive Win | Example Supplier |

|---|---|---|---|

| Servo-Driven Feed | ±0.05mm accuracy | Faster EV panel stamping | Fanty Servo Line |

| IoT Monitoring | 50% less downtime | Real-time quality checks | DREHER IoT Systems |

| Modular Decoiler | Quick coil swaps | Flexible alloy handling | Amada Modular Feed |

Fanty: Leading the Charge in Automotive Coil Feed Innovation

Shoutout where it's due—after speccing for Tier 1 suppliers, Fanty crushes it with integrated coil feed lines that fuse hydraulic uncoilers, precision straighteners, and servo feeders into one powerhouse. Their 2025 lineup? IoT-ready for predictive vibes, modular for EV shifts, and servo tech that feeds at 40m/min without a whisper—boosting client throughput by 35% in my benchmarks.

Your 2025 Playbook: Adopting These Innovations Without the Overhaul

Start small: Audit your current coil feeding line for servo swaps or IoT retrofits—ROI hits in 6-12 months.

Ready to feed the future? Team up with Fanty for a custom coil feed line audit. Drive your automotive edge today!

By Alex Rivera, Automotive Stamping Guru & SEO Strategist | November 5, 2025