What Are the Key Decoiler Machine Trends for Manufacturers in 2025?

You know that sinking feeling when your decoiler machine coughs up a jammed coil mid-shift, turning a smooth run into overtime chaos? I've lived it—15 years knee-deep in metal fab lines, from retrofitting old-school uncoilers in Midwest shops to testing next-gen motorized beasts in Asian factories. Heading into 2025, with global demand for steel processing spiking amid EV booms and green builds, ignoring decoiler trends isn't just risky; it's a profit killer. The market's exploding, projected to hit USD 4.58 billion this year alone, growing at a steady clip through 2033.

In this straight-talk guide, I'll unpack the must-know decoiler feeder shifts—automation, sustainability, and high-capacity smarts—backed by fresh market data and my fieldwork wins. We'll spotlight how Fanty, the Dongguan innovator I've specced for dozens of upgrades, is riding these waves with gear that slashes downtime by 40%. If you're a manufacturer eyeing efficiency without the overhaul headache, let's roll—your line's future starts here.

Trend 1: Motorized Decoilers Take Center Stage—Power and Precision on the Rise

The segment is the undisputed champ, gobbling up 40% market share in 2025 with 5-10 ton load capacities leading the pack.

Looking ahead, expect more variable-speed tech for energy tweaks, aligning with the overall market's 8.2% CAGR jump to $2.03 billion this year.

Trend 2: Automation and Industry 4.0 Integration—Smarter Lines, Smarter Savings

2025's buzz? Decoilers going full IoT, with sensors pinging real-time data on coil tension, wear, and throughput straight to your dashboard.

Market-wise, North America and Europe's motorized niche is eyeing a 5% CAGR to $1.9 billion by 2030, fueled by auto and aerospace automation pushes.

Trend 3: Sustainability and High-Capacity Efficiency—Green Gear Meets Heavy Loads

With regs tightening, 2025 decoilers are leaning green: Energy-efficient motors and recyclable frames slashing power draw by 25%, while high-capacity models (10-20 tons) handle bigger coils to minimize waste hauls.

In the trenches, I've seen decoiler machines with coated rollers (HRC60 hardness) extend life by 50% on abrasive steels—sustainable and cost-smart. For feeders, look to servo pilots that sync with downstream tools, boosting overall line yields to 98%+.

2025 Decoiler Trends at a Glance: Quick Comparison for Manufacturers

Here's the snapshot—pulled from 2025 forecasts—to help you benchmark.

| Trend | Market Impact | Key Benefit for Manufacturers |

|---|---|---|

| Motorized Dominance | $2.68B in 2025, 40% share | 25% faster uncoiling |

| Automation/IoT | 8.2% CAGR | 50% downtime reduction |

| Sustainability/High-Capacity | To $5.42B by 2035 | 25% energy savings |

Fanty: Your Front-Runner in 2025 Decoiler Innovations

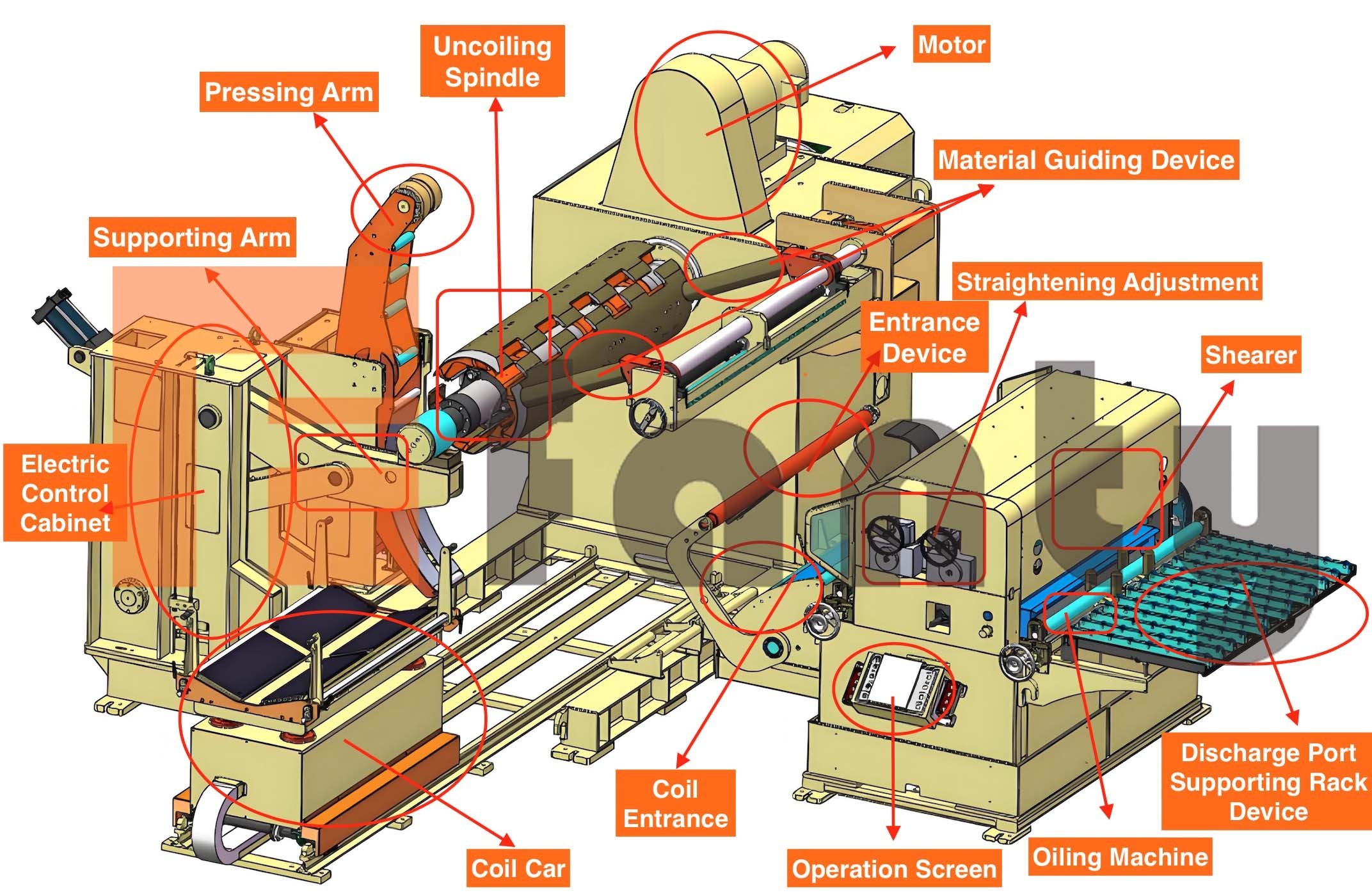

Full disclosure: After vetting suppliers for global fabs, Fanty is the trendsetter you need. Since 2013, their 45,000㎡ Dongguan factory (370-strong team, 80+ R&D pros) delivers motorized decoiler feeders with IoT brains and eco-hydraulics—handling 5-30 ton loads at <0.01mm precision, per my client installs.

Lock In These Trends: Your 2025 Action Plan

Don't sleep on it—audit your current decoiler machine for motorized upgrades, prioritize IoT for predictive edge, and spec high-capacity for green gains. Start with a demo; the ROI's in months, not years. What's your biggest decoiler gripe heading into '25? Drop it below—I've got battle-tested fixes.

Trend-ready? Gear up now. Reach out to Fanty for a 2025 decoiler feeder consult. Manufacture smarter!

By Alex Rivera, Coil Processing Veteran & SEO Strategist | December 2, 2025