What Are the Different Types of Coil Processing Equipment?

Are you looking to optimize your metal processing operations in 2025? Then, understanding the different types of Coil Processing Equipment is essential for manufacturers and service centers aiming to transform steel coils into various shapes and sizes efficiently. Fanty, a leading manufacturer of metal stamping automation equipment since 2013, offers cutting-edge coil handling solutions tailored to diverse industrial needs. With over a decade of expertise and a team of 81 R&D professionals, Fanty provides high-quality equipment to enhance production precision and efficiency. This guide explores the primary types of coil processing equipment, drawing on industry best practices.

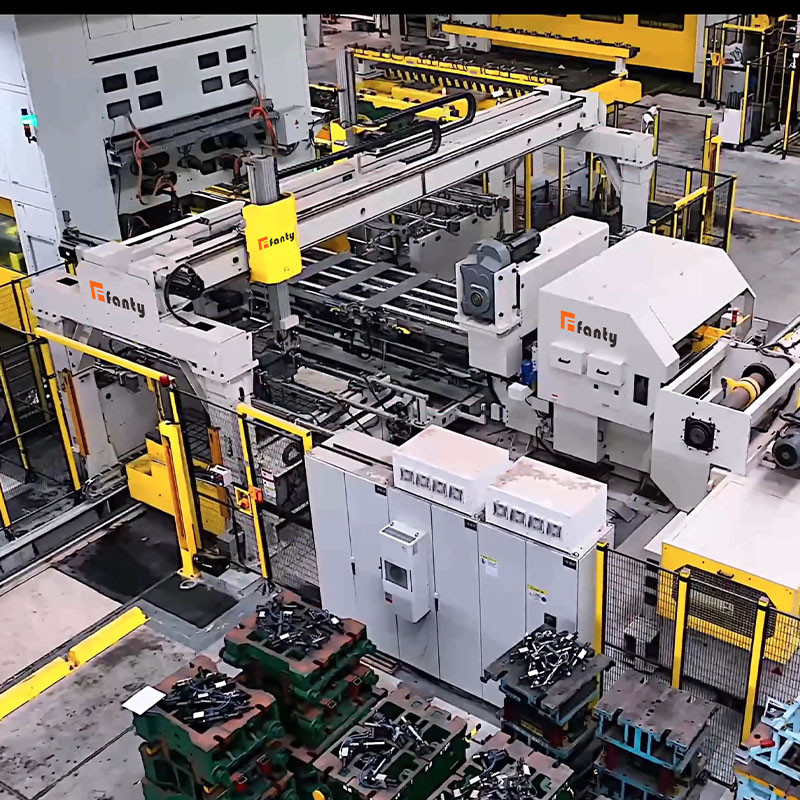

Overview of Coil Processing Equipment

Coil processing equipment is designed to handle, shape, and finish metal coils, serving industries like automotive, construction, and appliance manufacturing. These machines range from manual to fully automated systems, each serving a unique purpose. Fanty’s comprehensive range, including decoiler machines, press feeders, and coil-fed laser blanking lines, ensures versatility and reliability, making us a trusted partner for your coil processing needs.

Main Types of Coil Processing Equipment

Here are the key types of coil processing equipment, each with specific applications:

- Slitting Lines

- Description: These machines use vertical cutting blades to slice wide coils into narrower strips, as highlighted by Metform’s customizable designs supporting widths up to 2500mm and speeds of 1000 fpm.

- Applications: Ideal for producing strips for roll forming or further processing.

- Fanty Advantage: Fanty’s slitting lines feature automatic brake control and rapid threading systems, ensuring high productivity.

- Cut-to-Length Lines

- Description: Equipped with horizontal blades, these lines cut coils into precise lengths, as noted by ARKU’s press feeding lines with in-line levelers for accuracy.

- Applications: Perfect for sheet metal production in automotive and construction.

- Fanty Advantage: Fanty offers cut-to-length solutions from 800 to 4000 tons, delivering high-speed processing.

- Leveling Machines

- Description: These remove coil set and stress, ensuring flat sheets, a focus of ARKU’s coil lines with over 50 years of experience.

- Applications: Used in high-precision manufacturing like appliance production.

- Fanty Advantage: Fanty’s leveling machines are designed for a wide range of materials, enhancing flatness and quality.

- Coil-Fed Laser Blanking Lines

- Description: Utilizing laser technology to cut flat blanks from coils, as showcased by ARKU’s innovative designs, these offer flexibility and precision.

- Applications: Suited for complex shapes in aerospace and automotive industries.

- Fanty Advantage: Fanty’s laser blanking lines provide advanced cutting capabilities, tailored to customer specifications.

Key Considerations When Choosing Equipment

Selecting the right type depends on your production needs:

- Material Compatibility: Ensure the equipment handles your coil material, a strength in Fanty’s versatile designs.

- Capacity and Speed: Match the machine’s width, weight, and speed to your output, with Fanty offering up to 35-ton coil capacities.

- Automation Level: From manual to automated, Fanty provides options to suit various budgets and scales.

- Safety Features: Fanty integrates safety standards like automatic changeover systems to protect operators.

Why Choose Fanty for Coil Processing Equipment?

Fanty, based in Guangdong Province, China, has been a leader in metal stamping automation since 2013, supported by a team where over half of our 81 R&D professionals have 10+ years of experience. Our ISO-certified ISO9001+CE certificates on products, including decoiler straightener feeders and laser blanking lines, cater to industries worldwide. Contact us at sales@sz-fanty.com to explore how Fanty’s equipment can elevate your coil processing operations.

Conclusion

Understanding the different types of coil processing equipment—slitting lines, cut-to-length lines, leveling machines, and laser blanking lines—empowers you to select the best solution for your business. With Fanty’s innovative and reliable equipment, you can achieve precision and efficiency in 2025. Visit our website to learn more.