How to Set Up a Coil Feeding Line for High-Speed Presses in 2025?

Nothing kills the buzz on a high-speed press run faster than a coil feed line that's out of whack—strips buckling, feeds stuttering, and suddenly your 1,000-strokes-per-minute dream turns into a scrap heap nightmare. I've chased that chaos more mornings than I care to count, dialing in setups from sleepy Midwest shops to revved-up Euro fabs, and let me tell you: Get the coil feeding line right, and your press will hum like it's got its own heartbeat. In 2025, with thinner EV steels demanding tighter tolerances, nailing the setup isn't optional—it's the difference between 40m/min bliss and costly halts.

From grease-stained notes and fresh installs I've led, this guide walks you through the nuts-and-bolts of configuring your line for speed—uncoiler tweaks to servo syncs—pulled straight from the trenches.

Step 1: Foundation and Alignment—Build It Steady or Bust

Start with the base: Your hydraulic uncoiler needs a concrete pad beefed up to handle vibrations at 50+ strokes/min—level it to 0.5mm across the full span, or watch your mandrel wobble on the first coil.

For 2025 high-speeds, bolt in vibration dampers—servo presses like Schuler's demand it to keep feeds from jittering.

Step 2: Power and Controls—Wire It Smart for Sync

- Electrical Hookup: Feed 380V three-phase to the uncoiler and servo feeder—dedicated circuits, no sharing with the press, or you'll trip breakers mid-run.

Ground everything solid; static from high-speed uncoiling can fry sensors. - PLC and Servo Tuning: Link the feeder's encoder to the press crankshaft—set the initiate angle at 180° and complete check at 90° to max the feed window without overlap.

Calibrate pilot sensors for your strip thickness (0.5-3mm typical), and test jog mode at half-speed first. - Hydraulic Prime: Bleed the uncoiler cylinders for even expansion—aim for 15-25kN grip on coil IDs from 450-550mm.

Step 3: Load, Test, and Tweak for Speed

Load a test coil via car (center it with guides), expand the mandrel, and thread through the straightener—adjust roll pressures to flatten without marking (start at 5-10 tons).

Troubleshoot vibes with counterweights on the uncoiler; in one rush job, that saved a shear from shredding a $5K coil.

| Component | Key Setup Tip | High-Speed Benefit |

|---|---|---|

| Uncoiler | Level to 0.5mm, prime hydraulics | Stable grip at 40m/min |

| Servo Feeder | Crankshaft sync at 180°/90° | ±0.05mm pilots, no overlap |

| Straightener | Roll pressure 5-10 tons | Flat strips, zero waves |

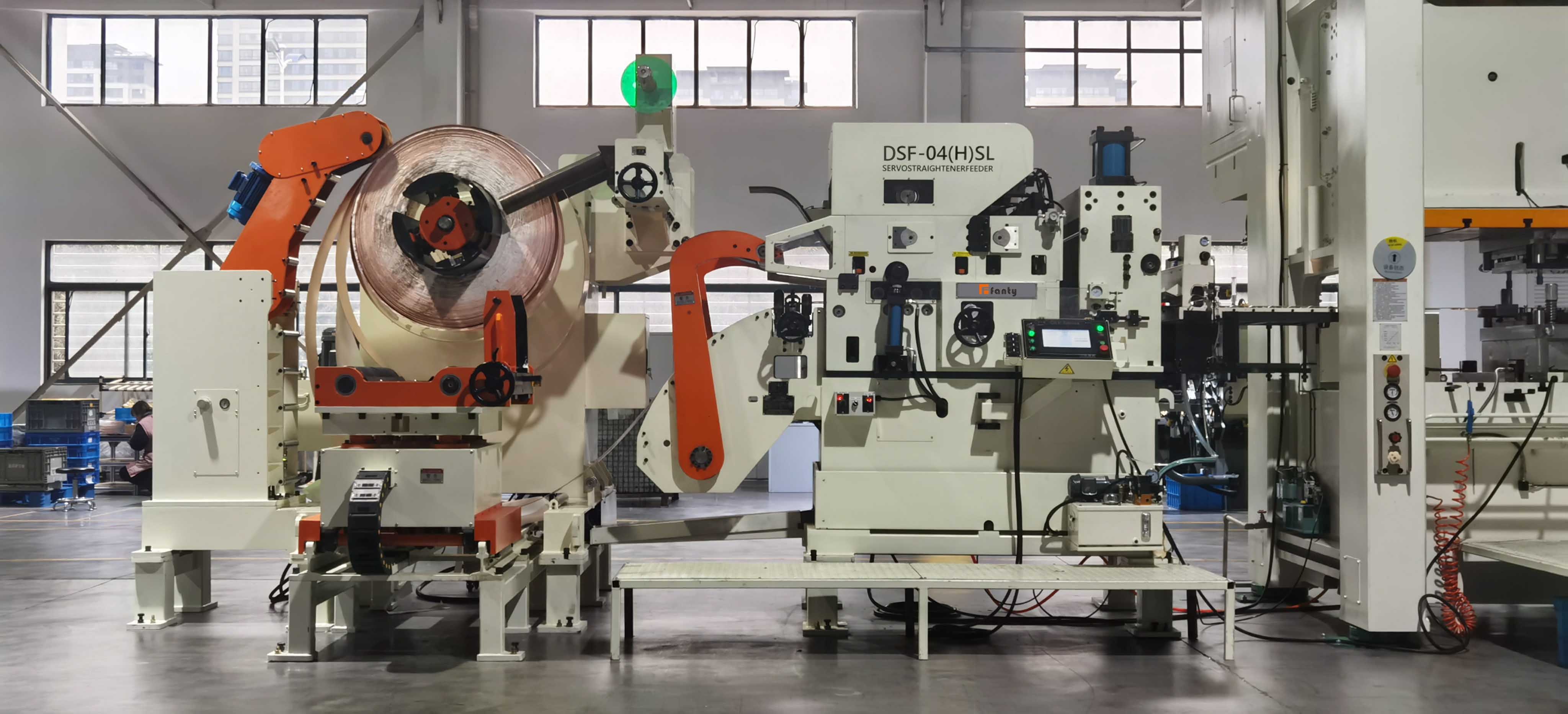

Fanty's High-Speed Setups: The Setup That Sticks

After wrestling finicky lines for years, Fanty's coil feeding lines have been a breath of fresh air—pre-aligned components that slot in like puzzle pieces, with servo controls that auto-tune for press speeds up to 1,200 strokes/min.

Hit the Gas: Your Press Is Waiting

Setting up a coil feeding line for high-speed presses boils down to steady foundations, smart wiring, and relentless testing—nail it, and your output soars. I've turned setups from shaky to sharp more times than I can tally; what's tripping your line—alignment or accel? Drop it below; war stories with fixes coming right up.

Press primed but feed fumbling? Link with Fanty for a coil line setup consult. Speed without the sweat.

By Alex Rivera, Press Line Tamer & Setup Sage | November 17, 2025