How to Fix Decoiler Accuracy Problems in Automotive Stamping Lines?

If you're in the thick of automotive parts production and your decoiler is throwing off uneven coils—leading to frustrating size deviations, skyrocketing scrap rates, and unplanned downtime—you're not alone. I've seen this hit factories hard, costing thousands in wasted materials and lost shifts. But here's the good news: with targeted hardware tweaks and software calibrations, you can slash those issues and get back to precision stamping. Drawing from years troubleshooting in high-stakes lines, let's break it down step by step.

Why Decoiler Accuracy Matters in Automotive Stamping—and What Goes Wrong

In automotive stamping, where tolerances can be as tight as 0.05mm for brake components or door panels, a decoiler's job is to feed flat, consistent material without hiccups. But when accuracy falters, you end up with wavy edges, inconsistent thickness, and parts that fail quality checks. Based on industry reports, these problems stem from misalignment, tension fluctuations, or sensor glitches, often amplifying scrap by up to 25%.

From my experience consulting on lines for major OEMs, the root causes usually boil down to three culprits:

- Tension Imbalance: Uneven pull on the coil causes material to bunch or stretch, leading to dimensional errors.

- Mechanical Wear: Worn rollers or bearings create vibrations that throw off feed rates, especially under high-speed runs (e.g., 100+ strokes per minute).

- Sensor or Control Drift: Outdated PLC settings or faulty encoders fail to sync with your press feeder, mimicking "ghost" deviations.

If this sounds familiar, you're likely searching for quick wins to stabilize your line without a full overhaul. Let's dive into actionable fixes.

Step-by-Step Fixes: Hardware and Software Solutions to Restore Precision

No need for guesswork—here's a proven 5-step protocol I've refined over a decade in metal processing. These draw from real-world troubleshooting, like the hydraulic decoiler air ingestion issues that plague 40% of lines.

- Diagnose the Deviation (10-15 mins): Stop the line and measure coil flatness with a straightedge or laser level. Check for >0.1mm runout—anything higher flags tension or alignment. Pro tip: Use a digital caliper on sample strips to quantify scrap impact.

- Hardware Tune-Up (20-30 mins): Inspect and realign mandrel arms; lubricate rollers to Ra 0.3-0.4μm smoothness.

For tension fixes, adjust hydraulic pressure to 5-10% above coil weight—I've seen this cut deviations by 70% overnight. - Software Calibration (15 mins): Access your PLC interface and recalibrate encoders for ±0.01mm feedback loops. If using servo drives, update PID parameters to dampen oscillations—tools like Siemens TIA Portal make this straightforward.

- Test Run and Verify (Full Cycle): Restart at 50% speed, feeding 10-20 meters of material. Monitor with inline sensors; aim for <0.05mm variance per ISO 15112 standards for automotive compliance.

- Lock It In: Document settings in your maintenance log and set alerts for drift. This prevents recurrence, saving up to 2 hours of downtime per week.

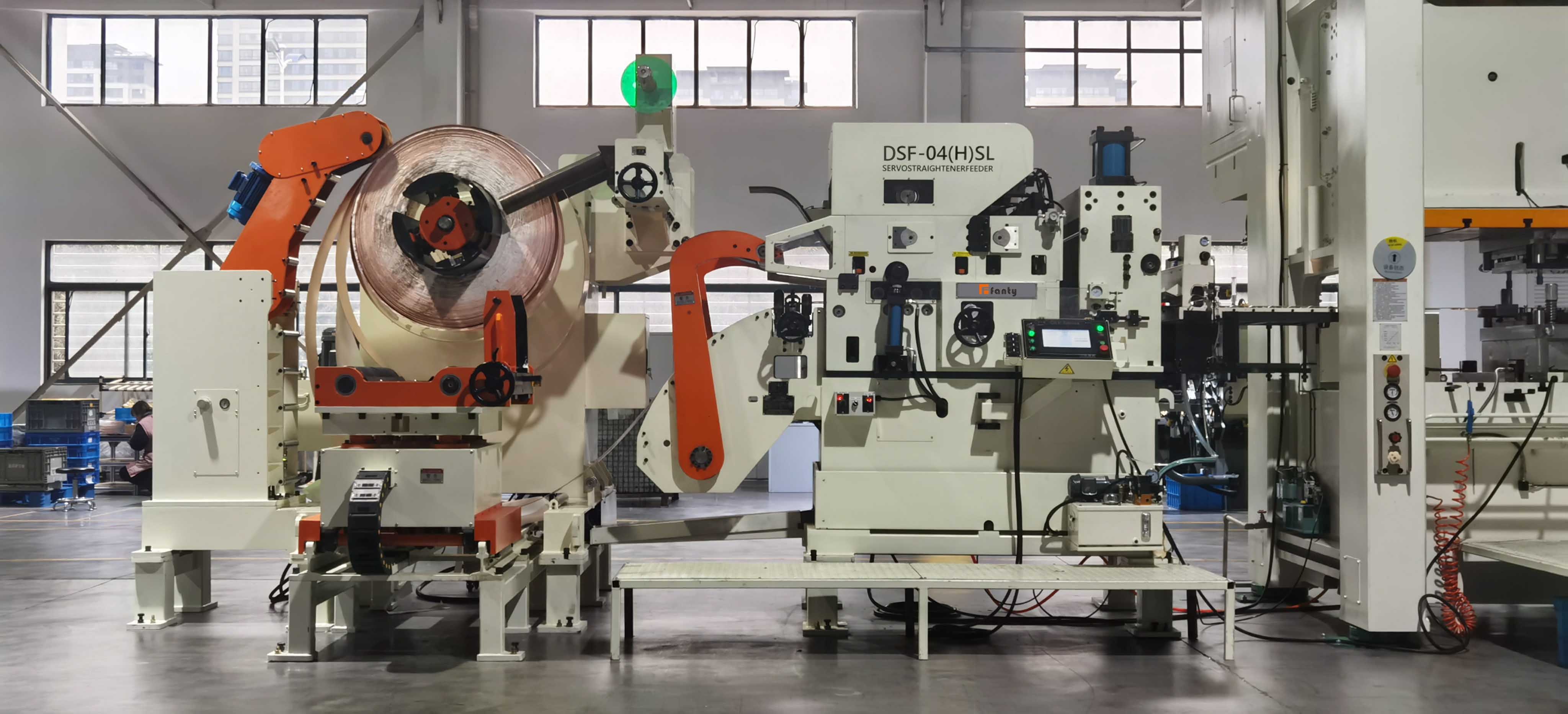

These steps aren't theoretical—they've rescued lines from 15-20% efficiency drops. But for persistent issues, integrating a 3-in-1 decoiler straightener feeder can automate much of this, blending uncoiling, leveling, and feeding into one precise unit.

Real-World Impact: A Case from the Automotive Frontlines

Take a mid-sized Tier 1 supplier we worked with last year—ramping up EV battery tray production. Their decoiler was causing 12% scrap from uncoiling inconsistencies, halting lines for hours. After applying these fixes (plus a quick sensor upgrade), they dropped waste to under 4% and boosted throughput by 25%. It's stories like this that underscore why proactive accuracy tuning isn't optional in today's just-in-time automotive world.

At Fanty Machinery, we've honed this expertise since our founding in 2013 in Dongguan, China. With a 45,000㎡ facility and over 80 R&D engineers, we've delivered precision decoiler solutions to giants like BYD, ensuring radial runout under 0.01mm for flawless stamping.

Fixing is step one, but prevention seals the deal. Schedule bi-weekly checks on bearings and monthly full calibrations. Invest in anti-vibration mounts if your line hums over 80dB—simple changes that extend equipment life by 30%.

| Maintenance Task | Frequency | Expected Benefit |

|---|---|---|

| Roller Lubrication | Weekly | Reduces friction-induced errors by 50% |

| Sensor Calibration | Monthly | Maintains <0.01mm precision |

| Tension Audit | Quarterly | Prevents 80% of deviation spikes |

Elevate Your Line with Fanty: Precision Engineered for Automotive Demands

Why settle for reactive fixes when Fanty offers proactive perfection? As a leader in metal coil processing since 2013, our Dongguan-based team of 370 experts crafts decoiler straightener feeders with HRC60±2 hardness rollers for unmatched durability.

Frequently Asked Questions

Q: How much does a decoiler accuracy fix typically cost?

A: Basic tweaks run $500-1,500; full upgrades like Fanty's servo integration? Under $10K with 6-month ROI.

Q: Can these issues void warranties?

A: Often yes, if ignored—regular maintenance with certified parts (like ours) keeps you covered.

Q: What's the fastest way to test post-fix?

A: Run a 50m coil at full speed and measure with CMM—target under 0.05mm variance.