How to Choose the Right Manual Decoiler | Expert Guide by Fanty

Selecting the right manual decoiler is crucial for optimizing your coil handling processes, especially in small to medium-scale manufacturing environments. A manual decoiler, known for its simplicity and cost-effectiveness, is an essential tool for unwinding metal, plastic, or paper coils into flat sheets for further processing. At Fanty, a leading manufacturer specializing in press automation equipment, we provide reliable decoiler solutions tailored to your needs. This guide draws on industry expertise to help you make an informed decision.

Understanding Manual Decoilers

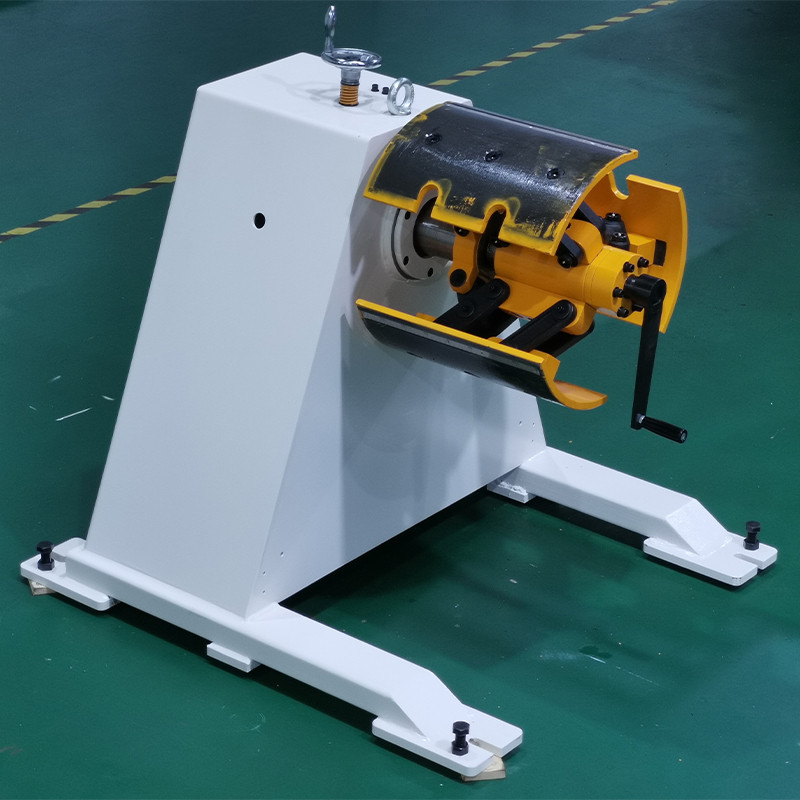

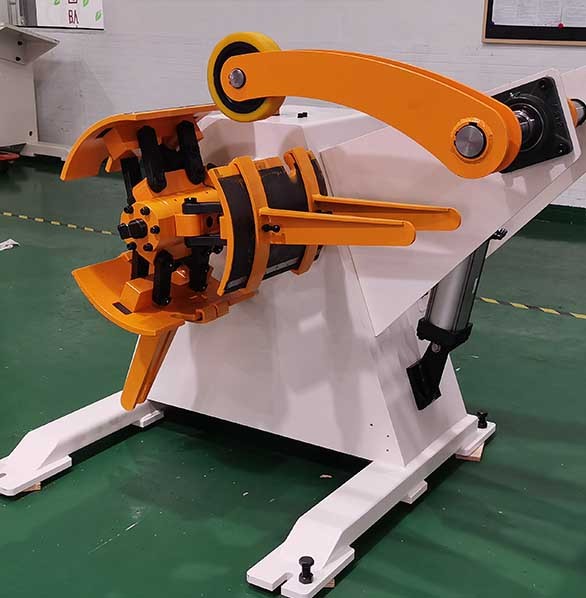

A manual decoiler operates without motorized components, relying on manual adjustments to unwind coils. Unlike hydraulic or automated models, it’s ideal for low-volume production and offers affordability and ease of use. According to insights from industry leaders, manual decoilers are best suited for coils with manageable weights and widths, making them a staple in workshops and small businesses. Fanty’s range of manual decoilers, crafted with precision, ensures durability and efficiency for diverse applications.

Key Factors to Consider

When choosing a manual decoiler, several factors determine its suitability for your operations:

- Load Capacity: The maximum weight the decoiler can handle is critical. For instance, the Manual Decoiler 60/8 from Stangroup supports up to 10,000 lbs, while Fanty offers models designed for loads from 2,000 to 10,000 lbs, catering to various production scales.

- Material Compatibility: Ensure the decoiler supports your coil material—metal coil. Fantyr’s versatile designs accommodate a wide range of materials, enhancing flexibility.

- Coil Width and Diameter: Match the decoiler’s specifications to your coil dimensions. The Ultimate Guide from others emphasizes adjustable mandrels, a feature integrated into Fanty’s products for seamless operation.

- Build Quality: Opt for robust construction to withstand daily use. Fanty uses high-grade steel and precision engineering, ensuring long-term reliability.

- Portability: For workshops with limited space, models offered by Fanty, provide easy mobility.

Practical Considerations

Beyond specifications, practical aspects influence your choice:

- Maintenance: Regular lubrication and cleaning, extend decoiler life. Fanty provides detailed maintenance guides with every purchase.

- Safety Features: Look for friction brakes and secure coil holders. Fanty’s models include safety enhancements to protect operators.

- Budget: Manual decoilers are cost-effective, with prices varying by capacity. Fanty offers competitive pricing and customizable options to fit your budget.

Why Choose Fanty?

Fanty, based in Guangdong Province, has over 13 years of experience in manufacturing decoiling and feeding equipments. Our commitment to quality and innovation is reflected in our ISO-certified processes and a wide product range, including manual decoilers, straighteners, and 3-in-1 feeder systems. We serve industries like automotive, construction, and appliance manufacturing, delivering tailored solutions from our state-of-the-art facility. Contact us at sales@sz-fanty.com for expert advice or to request a quote.

Conclusion

Choosing the right manual decoiler involves balancing capacity, compatibility, and practicality while considering your budget and safety needs. By leveraging the expertise from industry resources and the reliable products from Fanty, you can enhance your production efficiency. Explore our catalog today to find the perfect decoiler for your business.