How to Choose the Right Decoiler in 2025 ?

By Fanty Experts | Published: September 08, 2025

Decoilers are indispensable in metal processing, and understanding their types—manual, hydraulic, and motorized—is key to selecting the right one for your needs in 2025. At Fanty Machinery, with our 45,000㎡ facility and 80+ R&D experts since 2013, we offer a full range of decoilers tailored to industries like automotive and construction. This comprehensive guide explores each type's features, benefits, applications, and how Fanty’s innovations can enhance your operations, ensuring efficiency and reliability.

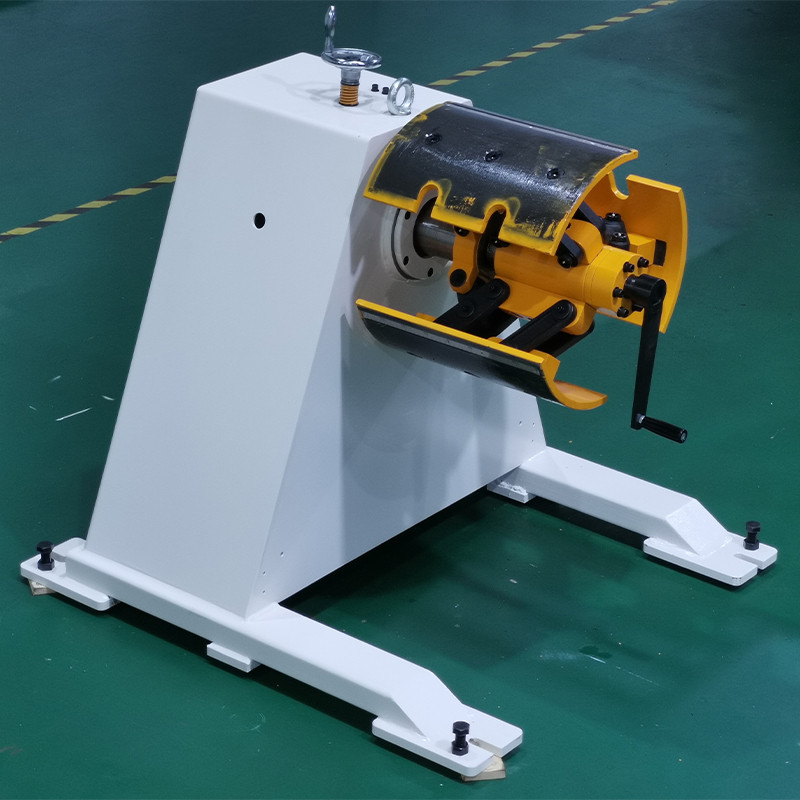

Manual Decoilers: Simple and Cost-Effective

Manual decoilers are basic models operated by hand, ideal for small-scale operations with light coils. They feature a simple mandrel and brake system for tension control.

Fanty’s manual decoilers are built with durable steel frames, supporting up to 5 tons, and are perfect for startups. Our customer-focused approach ensures easy maintenance and customization.

Hydraulic Decoilers: Power for Heavy-Duty Tasks

Hydraulic decoilers use hydraulic pressure for mandrel expansion and coil gripping, suitable for thick materials and high volumes.

Fanty’s hydraulic models handle 20+ tons, with features like automatic centering, making them ideal for automotive applications. Our 10+ years of expertise ensure they integrate seamlessly with stamping lines.

Motorized Decoilers: Efficiency with Automation

Motorized decoilers use electric motors for consistent unwinding, offering variable speeds via VFDs.

Fanty’s motorized decoilers feature PLC controls for precision, reducing operator fatigue and increasing output by 25% in case studies.

Comparing the Types

Manual: Low cost, high labor. Hydraulic: High capacity, automated. Motorized: Balanced efficiency.

Applications and Case Studies

From construction to electronics, each type shines in specific scenarios. Fanty’s hydraulic decoilers have boosted productivity for automotive clients by 30%.

Frequently Asked Questions

Which type is best for heavy coils?

Hydraulic decoilers, like Fanty’s, for loads over 10 tons.

How do motorized decoilers save time?

Through variable speed control, reducing manual adjustments.

Conclusion

Choosing the right decoiler type is key to efficiency. Fanty’s range ensures you get the best fit. Contact us for expert advice.

About Fanty

Fanty Machinery, founded in 2013, is a leader in stamping automation and professional manufacturer of coil processing equipments. Visit decoilerfeeder.com.