How to Choose the Best 3-in-1 Decoiler Straightener Feeder for Automotive Stamping?

Posted on January 05, 2026 | By Dr. Li Wei, Lead R&D Engineer at Fanty Machinery

In the high-stakes world of automotive stamping, where a single coil feed error can scrap an entire batch of brake rotors or fenders, picking the right 3-in-1 decoiler straightener feeder isn't just smart—it's essential. I've led R&D on these beasts for over 15 years, watching factories shave hours off setup times and boost yields by 25% with the perfect unit.

Step 1: Prioritize Precision and Material Compatibility for Tight Tolerances

Automotive stamping demands flawless flatness—think AHSS steels or aluminum alloys that warp at the slightest feed glitch.

Step 2: Evaluate Speed, Integration, and Space Efficiency for Non-Stop Production

Your line's only as fast as its slowest feed—aim for 20-30m/min uncoiling synced to 120+ strokes/min presses.

Step 3: Factor in Durability, Maintenance, and Cost of Ownership

Upfront price tags (starting $50K for entry models) tempt, but total ownership seals the deal—target 5-7 year lifespans with minimal downtime.

Step 4: Test for Real-World Automotive Fit—Workflow and Scalability

Theory's fine, but simulate your workflow: Does it handle zigzag feeding for complex contours or multi-material switches without recalibration?

Step 5: Partner with Proven Experts for Customized Excellence

The best choice? One tailored to *your* line. Factor in OEM flexibility—custom roll configs or software tweaks for specific alloys.

A Stamping Success Story: From Chaos to Precision with the Right 3-in-1

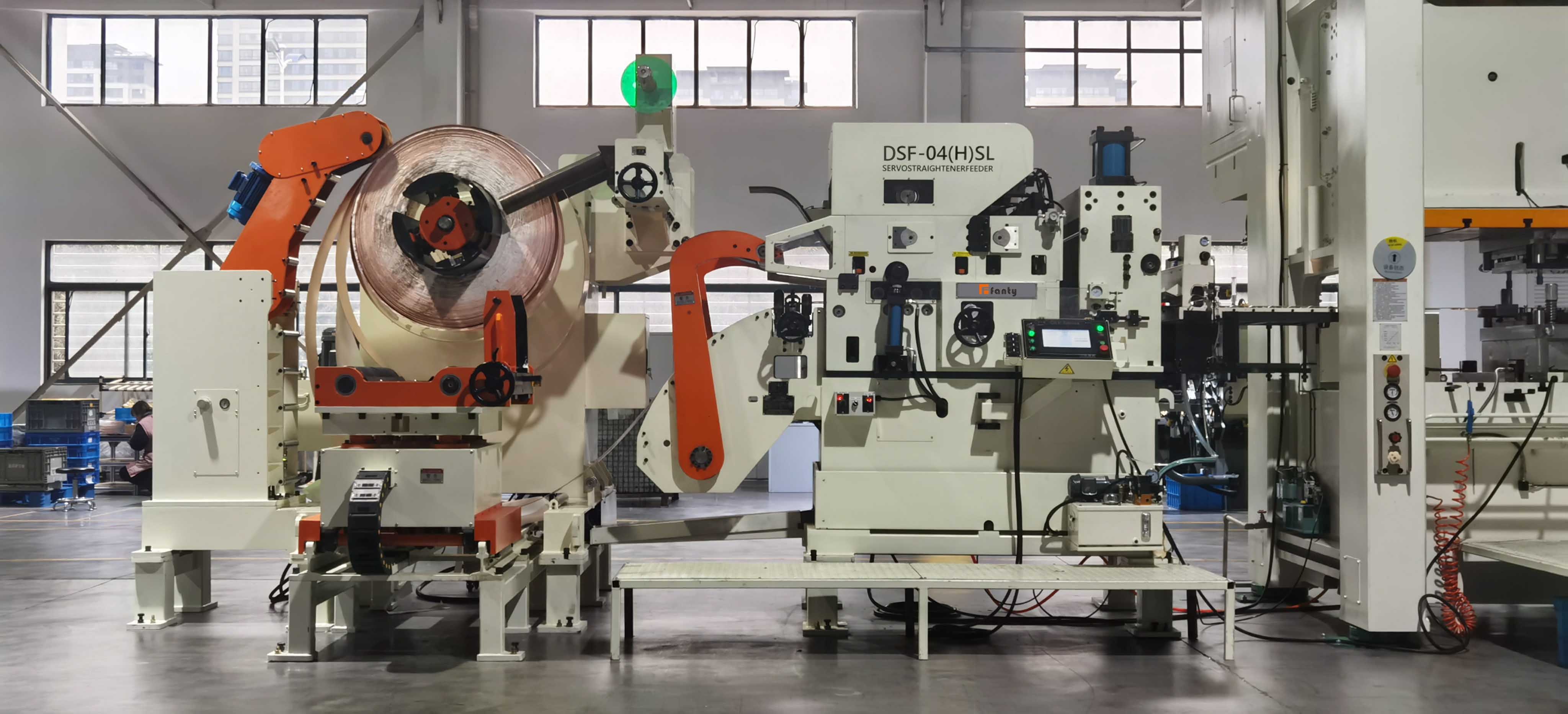

Recall a 2025 rollout for a U.S. Tier 2 supplier battling separate-machine bottlenecks on seat frame lines—scrap at 8%, setups dragging 2 hours. We spec'd a Fanty DSF4-1300H: Integrated workflow dropped defects to 1.5%, setups to 20 minutes, and ROI hit in 4 months.

Find Your Ideal 3-in-1 with Fanty: Let's Customize It

Why guess when Fanty engineers precision from the ground up? Our 370-expert team, with global installs since 2018, crafts decoiler straightener feeders that evolve with your automotive needs—from AHSS to recycled alloys. Trusted by innovators, we're ready to audit your line and quote a bespoke solution. Get your free selection guide today—transform your stamping tomorrow.

Frequently Asked Questions

Q: What's the ideal thickness range for automotive 3-in-1 feeders?

A: 0.3-6mm for most AHSS/EV apps—Fanty's handle up to 12mm for versatility.

Q: How does integration affect ROI?

A: Space and time savings yield 20-30% efficiency gains, payback in 6-12 months.

Q: Can Fanty customize for my press?

A: Yes—tailored servos and rolls for any OEM, with full support.