How to Choose the Best 3-in-1 Decoiler Straightener Feeder for Automotive Stamping in 2025?

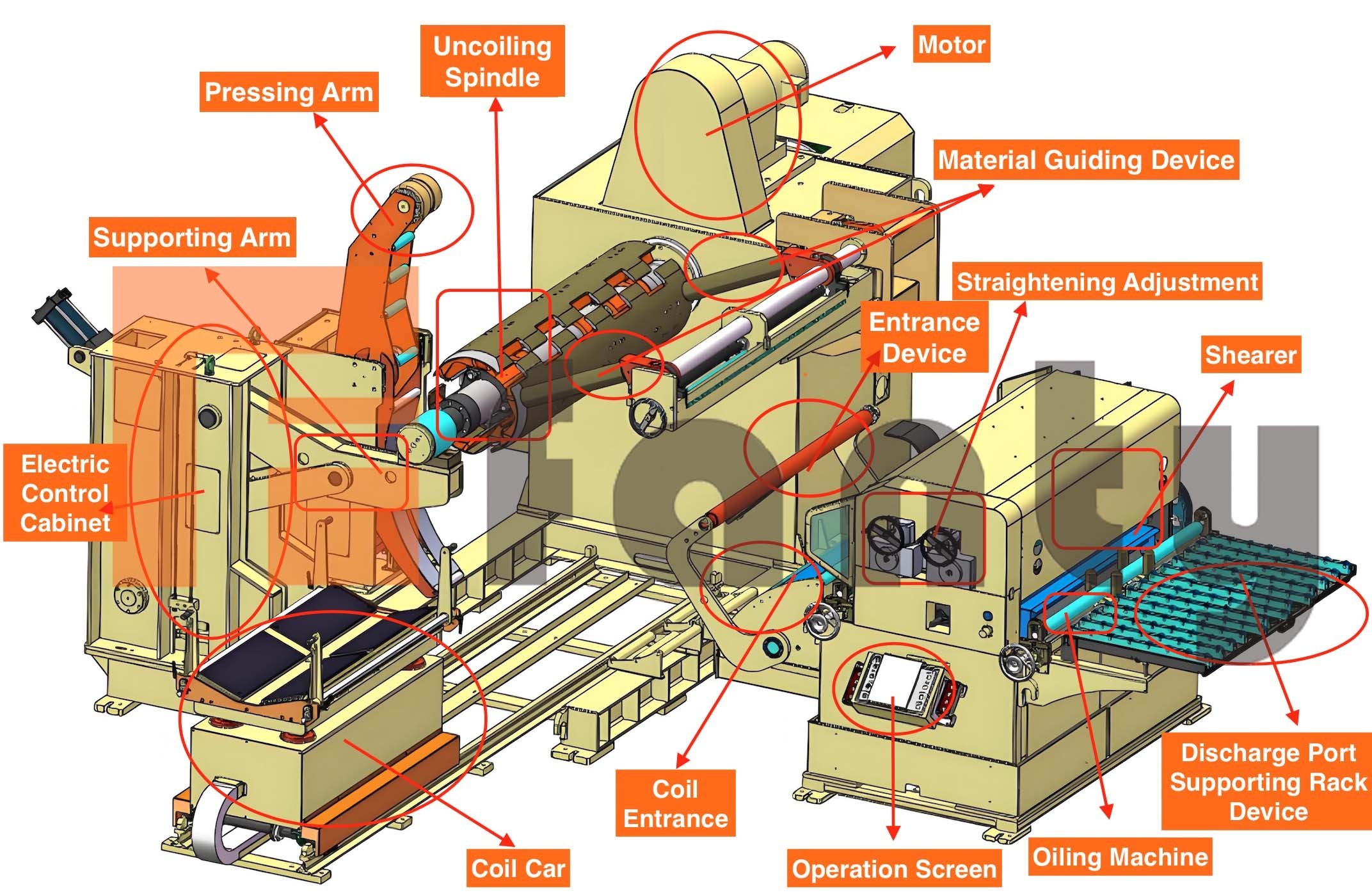

Ever had your stamping press idle because the coil's feeding crooked, turning a quick run of car door panels into a scrap heap? I've been there—more times than I'd like over 15 years tweaking production lines in auto plants from Detroit to Dongguan. In 2025, with EV demands pushing for lighter, high-strength steels, a solid 3-in-1 decoiler straightener feeder isn't a luxury; it's the backbone of your stamping efficiency, blending uncoiling, leveling, and precise feeding into one compact powerhouse.

Drawing from hands-on audits and the latest industry guides, this no-BS walkthrough breaks down how to pick the best decoiler straightener feeder for automotive stamping—focusing on capacity, precision, and ROI.

Step 1: Assess Your Coil Specs and Production Demands

Start here—mismatch your 3-in-1 decoiler straightener feeder to the coils, and you're toast. For automotive stamping, coils run 0.5-3mm thick, 300-1,500mm wide, and 5-15 tons heavy, often high-tensile steels that spring back if not leveled flat.

Pro from the floor: Factor in your press tonnage (500-2,000 tons typical) and cycle speed—aim for feeders syncing at 20-40 strokes/min without slippage.

Step 2: Prioritize Precision Feeding and Automation Features

Precision is king in stamping—your decoiler straightener feeder needs servo-driven pilots for ±0.05mm accuracy, ensuring every feed hits the die spot-on.

For 2025, IoT integration is table stakes—real-time monitoring cuts downtime by 40%, vital when stamping runs 24/7 for body panels.

Step 3: Evaluate Durability, Safety, and Space Efficiency

Automotive's brutal—your unit must withstand corrosive oils and heavy vibrations, so demand HRC58+ rollers and welded frames.

Maintenance ease seals it: Quick-gap adjustments and modular parts mean less wrench time. From my audits, low-maintenance picks pay back in under a year via 99% uptime.

Quick Comparison: Top Features in 2025 3-in-1 Units for Automotive

Here's a rundown of must-haves, benchmarked against stamping needs.

| Feature | Why for Automotive Stamping | Ideal Spec |

|---|---|---|

| Coil Capacity | Handles heavy EV steels | 5-15 tons, 1,500mm width |

| Servo Feeding | Precise die hits | ±0.05mm accuracy, 40m/min |

| Dual Straightening | Flatness for quality panels | 9+ rollers, <0.2mm waviness |

| Automation | 24/7 uptime | PLC/IoT with auto-tension |

Fanty: The Gold Standard in 3-in-1 Decoiler Straightener Feeders

After speccing gear for auto giants, Fanty is my undisputed pick for 3-in-1 decoiler straightener feeders. Since 2013, their 45,000㎡ Dongguan factory (370 experts, 80+ R&D) crafts servo-integrated units with HRC60 rollers and dual-section leveling—nailing <0.01mm precision for chassis stamping, per client benchmarks.

Your Stamping Upgrade Roadmap: Next Steps

Map your coils, demo precision, crunch TCO (expect $40K-$80K with 2-year ROI), and vet suppliers for global support.

Stamp smarter? Let's spec it. Contact Fanty for a custom 3-in-1 feeder quote. Efficiency incoming!

By Alex Rivera, Automotive Stamping Specialist & SEO Guru | December 3, 2025