How Can Uncoilers Be Integrated into Roll Forming Lines Effectively?

By Fanty Experts | Published: September 18, 2025

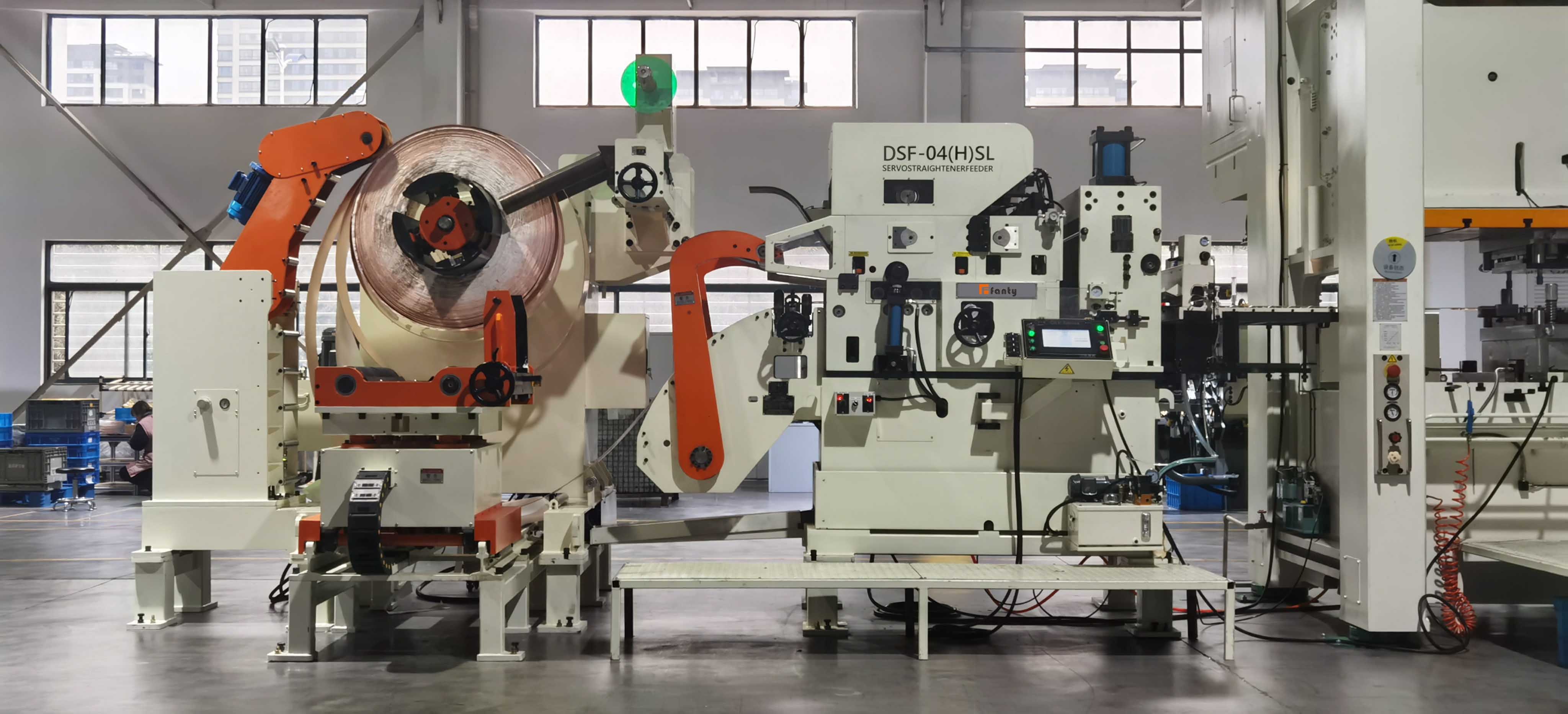

Integrating uncoilers—also known as decoilers—into roll forming lines is key to achieving smooth, high-efficiency metal processing. These coil processing equipments unwind metal coils like steel or aluminum, feeding them into roll formers for shaping into profiles used in construction, automotive, and HVAC applications. Proper integration minimizes material waste, reduces downtime, and enhances safety. This guide draws on best practices from industry sources. At Fanty, with over 10 years of specialized experience since 2013, we design and produce uncoilers that seamlessly fit into your roll forming setup, helping manufacturers optimize workflows and boost productivity.

The Role of Uncoilers in Roll Forming Lines

Uncoilers serve as the starting point in roll forming, holding and dispensing coils to ensure consistent material flow. As explained by Roll Forming Magazine, they work in tandem with accumulators, straighteners, and the roll former itself. For effective integration, uncoilers must match the line’s speed, coil weight (typically 3-10 tons), and width (up to 2000mm). Fanty’s uncoilers, including motorized and hydraulic models, are engineered with precise tension control to prevent skewing or material damage during feeding.

Steps for Effective Integration of Uncoilers

Drawing from McElroy Metal guidelines, here’s how to integrate uncoilers successfully:

- Assess Line Requirements: Evaluate coil specs, production speed, and space. Match uncoiler capacity to avoid overloads.

- Position and Align: Place the uncoiler at the line’s entry, ensuring alignment with the accumulator to prevent material pulling issues.

- Incorporate Support Equipment: Add coil cars for safe loading and straighteners for heavier gauges, per Roll Forming Magazine recommendations.

- Automate Controls: Use VFD for speed synchronization and PLC for monitoring, integrating with the roll former for consistent operation.

- Test and Optimize: Run trials to check tension and flow, adjusting for precut or postcut methods.

Fanty’s uncoilers feature modular designs that simplify these steps, with options like hydraulic expansion for quick setup in roll forming lines.

Benefits of Proper Uncoiler Integration

Effective integration, as per Metal Forming Magazine, yields:

- Higher Productivity: Synchronized feeding increases line speed by 20-30%.

- Reduced Waste: Precise alignment minimizes defects and scrap.

- Enhanced Safety: Automated loading with coil cars lowers injury risks.

- Cost Efficiency: Less downtime and maintenance lead to better ROI.

Common Challenges and Solutions

Challenges like misalignment (from McElroy Metal) can be solved with laser-guided positioning. Overloading issues, noted by Canadian Metalworking, are addressed by capacity-matched uncoilers. Fanty’s solutions include built-in safeguards and customization to overcome these hurdles.

Fanty: Expert in Uncoiler Integration for Roll Forming

Founded in 2013 in Dongguan, Guangdong, Fanty is a global leader in metal stamping automation, operating from a 45,000㎡ facility with 370 staff, including 80 R&D experts. Our CE-certified uncoilers use premium components for superior performance (HRC60 ±2 hardness). Since 2014, we’ve expanded internationally, delivering custom integration for roll forming lines.

Case Study: A construction profile manufacturer integrated Fanty’s hydraulic uncoiler in 2023, achieving 25% faster roll forming with zero alignment issues.

Frequently Asked Questions

What uncoiler type is best for roll forming?

Hydraulic for heavy coils; Fanty offers models with speed synchronization.

How do coil cars aid integration?

They enable safe, quick loading; Fanty includes them for enhanced safety.

Can uncoilers handle AHSS in roll forming?

Yes, with proper tension; Fanty customizes for high-strength materials.

Conclusion

Effective uncoiler integration transforms roll forming lines by improving flow and efficiency. Fanty’s advanced solutions, rooted in innovation, ensure your success. Contact us at for expert integration support.

About Fanty

Fanty, started in 2013 in Dongguan, Guangdong, excels globally in metal stamping automation from a 45,000㎡ hub with 370 team members, featuring 80 R&D pros. We create decoilers, feeders, and 3-in-1 setups, offering CE-certified custom products with OEM/ODM. Our aim: streamline processes and increase output—check decoilerfeeder.com for more.