Can FANTY's Advanced Metal Stamping Automation Equipment Revolutionize Your Automotive Parts Stamping?

In the highly competitive world of automotive parts manufacturing, the demand for high-quality metal stamping automation equipment and custom solutions to enhance productivity and precision is constantly on the rise. Automobile giants like BYD, Mercedes-Benz, and BMW, among others, rely on top-notch suppliers to meet their stringent requirements for automotive parts stamping. However, these manufacturers often encounter challenges such as long lead times, quality inconsistencies, and inefficiencies in coil handling—all of which can hinder production goals. FANTY, a leading provider of advanced metal stamping automation equipment, specializes in delivering innovative solutions that address these pain points, ensuring seamless integration into production lines and driving measurable improvements for businesses worldwide.

The Challenges Faced by Automotive Parts Stamping Manufacturers

Long Product Lead Times

One of the most common pain points for automotive parts stamping manufacturers is the long product lead times. In a report by the Automotive Supply Chain Council, it was stated that approximately 60% of automotive parts manufacturers experienced delays in product delivery from their suppliers in the past year. Long lead times can disrupt the entire production schedule, leading to increased inventory costs, missed deadlines, and potential losses in business opportunities. For example, if a supplier fails to deliver the necessary metal stamping equipment on time, the automotive parts manufacturer may have to halt their production line, resulting in significant financial losses.

Quality and Precision Issues

Product quality and precision are non - negotiable in the automotive industry. Even the slightest deviation from the required specifications can lead to serious safety hazards and a negative impact on the vehicle's performance. A study conducted by Automotive Quality Institute revealed that about 35% of automotive recalls were directly related to component quality issues. When it comes to metal stamping, precision is crucial. Inaccurate stamping can lead to parts that do not fit properly, affecting the assembly process and ultimately the quality of the finished vehicle. Automotive parts stamping manufacturers are constantly on the lookout for suppliers who can provide equipment that ensures consistent quality and high precision.

Safety and Efficiency Concerns in Coil Handling

Coil handling is an integral part of the metal stamping process, especially when dealing with metal coils as raw materials. Safety during coil handling is a major concern, as improper handling can lead to accidents, injuries, and damage to the equipment. According to the Occupational Safety and Health Administration (OSHA), there are approximately 1,500 coil - handling - related injuries reported each year in the manufacturing industry. Additionally, the efficiency of coil handling directly impacts the overall production speed. Slow or inefficient coil handling can bottleneck the production process, reducing productivity. Automotive parts stamping manufacturers need reliable and safe coil handling equipment to ensure smooth operations.

Concern | Impact on Automotive Parts Stamping | ||

| ‣ Long lead times | Disrupts production schedule, increases inventory costs, and may lead to loss of business opportunities | ||

| ‣ Quality and precision issues | Can cause safety hazards, affect vehicle performance, and lead to product recalls | ||

| ‣ Safety concerns in coil handling | Risk of accidents, injuries, and equipment damage | ||

Efficiency concerns in coil handling | Bottlenecks production process, reduces overall productivity |

FANTY's Comprehensive Metal Stamping Automation Equipment Solutions for Automative Parts Producing

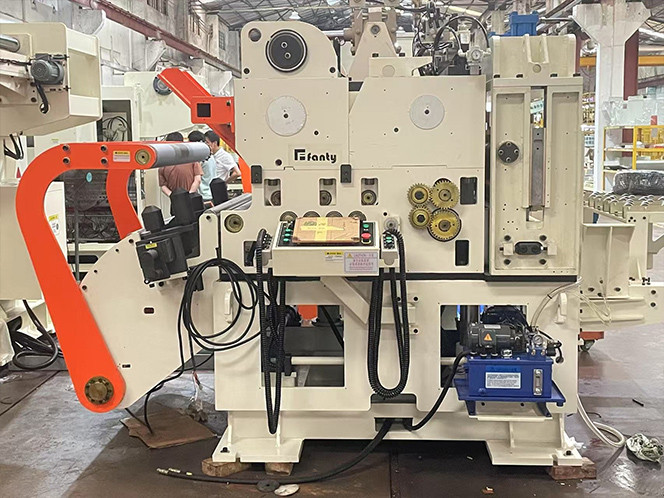

1. High - Quality Metal Coil Uncoilers Straightener Feeder for Metal Coil Handling

FANTY's metal coil handling equipments are designed to provide a seamless handling to the metal stamping process. Among them, our DSF Models, Decoiler Straightener Feeders, are a compact equipment specially designed for Automated processing of metal coils in the automative parts stamping line. It is equipped with advanced technology (integrating the uncoiler part, straightener part and feeder part into the one machine) that ensures smooth and controlled unwinding, leveling and feeding of metal coils. For instance, our servo - driven uncoilers offer precise speed control, which is essential for maintaining the integrity of the metal sheet during the uncoiling process. According to industry experts at MetalForming Magazine, a well - designed DSF model can reduce material waste by up to 15% compared to traditional models. FANTY's DSF models are also built with safety features such as emergency stop buttons and protective barriers to minimize the risk of accidents during operation.

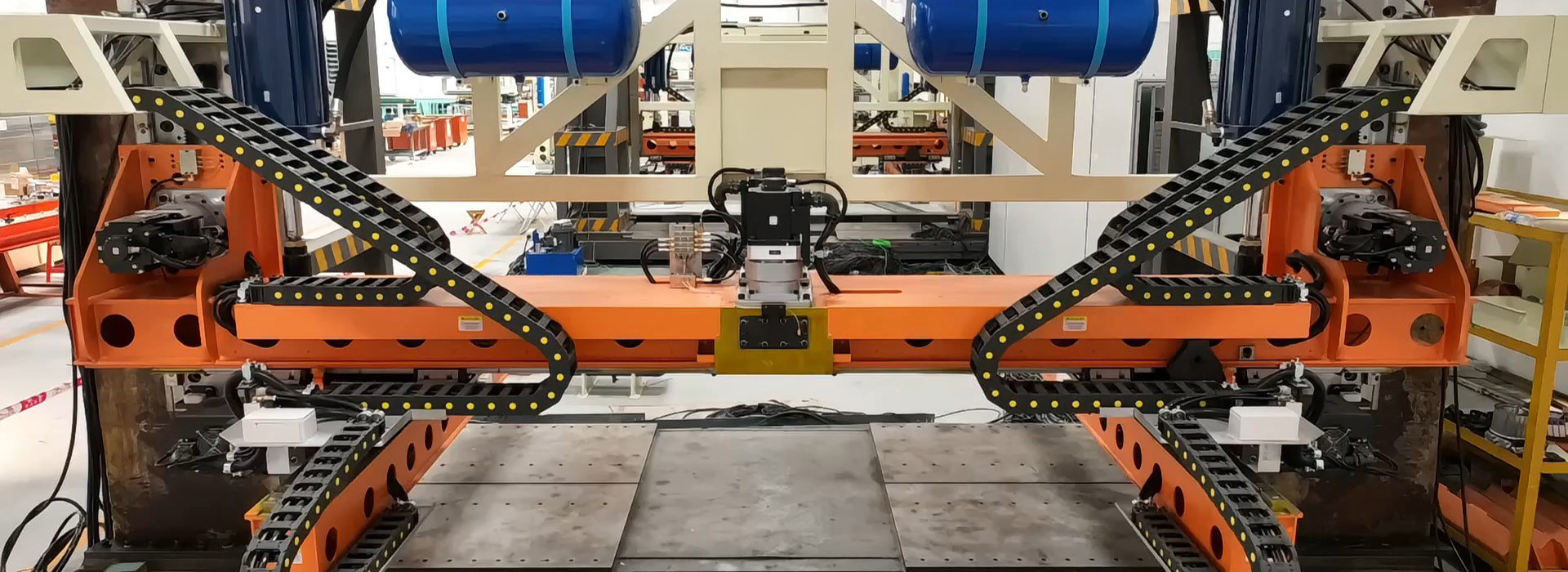

2. Advanced Sheet Separators (Destacker System) for Sheet Plate Destacking to the Press

Normally, there is a optional mechanism- hydraulic shearer. After metal coils are cut into the sheets by the Shearer of our DSF models, then the sheet separator (destacker system) will be applied into the automated press line for automative parts producing. Sheet separators (De-stacker system) play a crucial role in ensuring the smooth flow of metal sheets during the stamping process.

FANTY's sheet separators use advanced technologies such as air - blow and vacuum - hold systems to separate individual sheets from the stack accurately. This prevents double - feeding, which can cause damage to the stamping tool and result in defective parts. Our sheet separators are also highly customizable, allowing them to be integrated seamlessly with other FANTY equipment and existing production lines.

Powerful Stamping Presses

FANTY's stamping presses are the heart of the metal stamping process. Our presses are available in a wide range of tonnages and configurations to meet the diverse needs of automotive parts stamping manufacturers. Whether it's a small - scale production of intricate components or large - scale production of body panels, our presses can deliver consistent and high - quality results. Our presses are also designed with energy - saving features, which can significantly reduce operating costs. As stated in a report by the International Energy Agency (IEA), energy - efficient manufacturing equipment can contribute to a 10 - 15% reduction in overall energy consumption in the manufacturing sector.

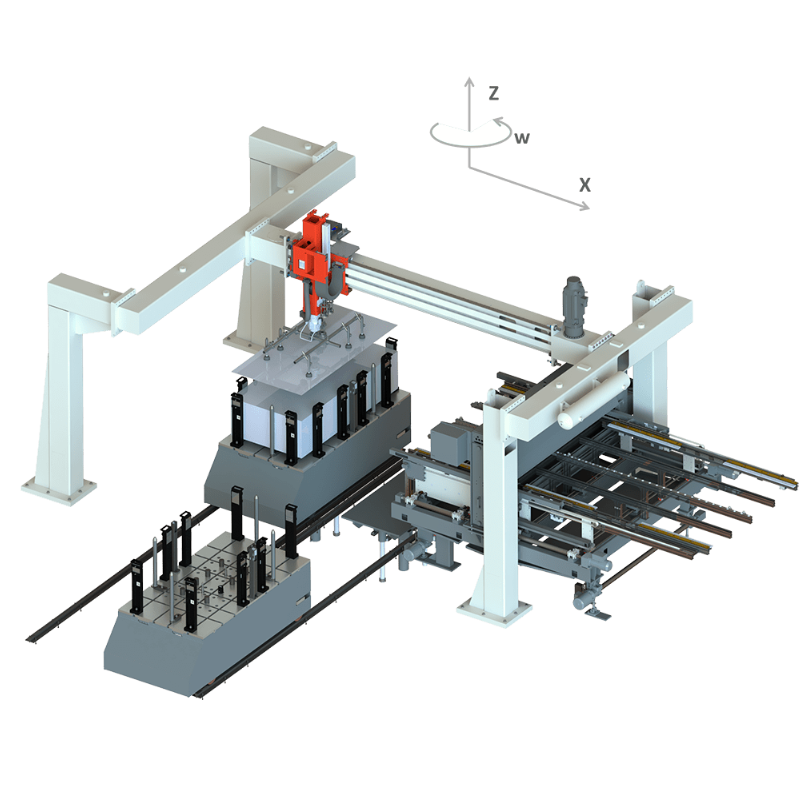

Intelligent Robot Systems (Transfer System)

FANTY's robot systems( transfer system) bring a new level of automation to the metal stamping process. These can perform tasks such as part transfer, loading, and unloading with high speed and precision.

By replacing manual labor with robot systems, automotive parts stamping manufacturers can significantly reduce labor costs, improve production efficiency, and enhance workplace safety. According to a study by McKinsey Global Institute, the use of robotics in manufacturing can increase productivity by up to 30% and reduce labor costs by 20 - 25%.

Custom Solutions for Unique Requirements

FANTY understands that every automotive parts stamping manufacturer has unique requirements. That's why we offer custom metal stamping automation solutions tailored to the specific needs of our clients. Our team of experienced engineers works closely with clients to understand their production processes, challenges, and goals. Based on this in - depth understanding, we design and develop customized solutions that optimize production efficiency, improve product quality, and reduce costs.

For example, a client in the automotive industry was facing challenges in stamping complex - shaped parts with high precision. Our engineering team analyzed their requirements and designed a custom stamping cell that combined our high - precision stamping press, advanced coil feeder, and intelligent robot system. The result was a significant improvement in the quality of the stamped parts, with a reduction in the rejection rate from 8% to 2%. Additionally, the production speed increased by 15%, meeting the client's production targets.

Assurance of Quality and After - Sales Service

Quality Assurance

FANTY is committed to providing products of the highest quality. We have a comprehensive quality management system in place that adheres to international standards such as ISO 9001. All our metal stamping automation equipment undergoes rigorous testing at every stage of production, from raw material inspection to final product testing. Our quality control team uses advanced testing equipment and techniques to ensure that each product meets or exceeds the required specifications.

After - Sales Service

We believe that excellent after - sales service is just as important as the quality of our products. FANTY offers on - site installation, commissioning, and training services to ensure that our clients' equipment is installed correctly and operated safely and efficiently. Our team of technicians is available 24/7 to provide technical support and troubleshooting services. In addition, we offer regular maintenance services to keep the equipment in optimal condition, extending its lifespan and ensuring consistent performance.

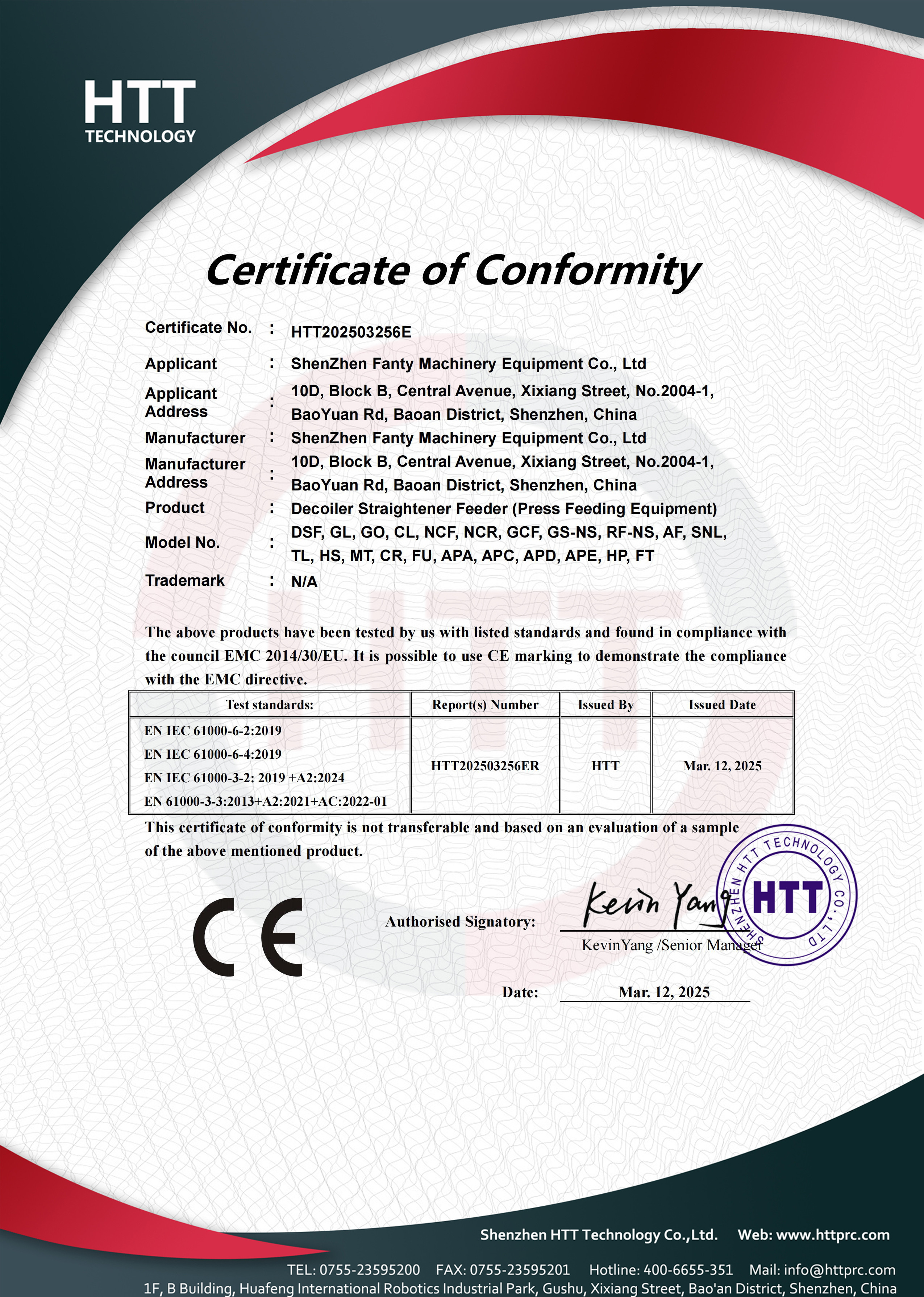

Company Qualifications and Certificates

FANTY holds a number of industry - recognized qualifications and certificates, which are a testament to our commitment to quality and excellence. Our ISO 9001 certification for quality management system compliance, along with CE EMC certificate and CE LVD certificate, gives our clients the confidence that they are partnering with a reliable and professional supplier.

Conclusion

In conclusion, FANTY's advanced metal stamping automation equipment and custom solutions offer the perfect answer to the challenges faced by automotive parts stamping manufacturers. By choosing FANTY as your partner, you can revolutionize your automotive parts stamping process, achieving higher productivity, better quality, and greater cost - effectiveness. Contact us today to learn more about how we can help your business thrive in the competitive automotive industry.

References

‣ Automotive Supply Chain Council. (n.d.). Industry Report on Supplier Delivery Delays. Retrieved from https://www.automotivesupplychaincouncil.org/

‣ Automotive Quality Institute. (n.d.). Study on Automotive Recalls and Component Quality. Retrieved from https://www.automotivequalityinstitute.org/

‣ Occupational Safety and Health Administration. (n.d.). Coil Handling - Related Injury Statistics. Retrieved from https://www.osha.gov/

‣ MetalForming Magazine. (n.d.). Analysis of Uncoiler Efficiency and Material Waste Reduction. Retrieved from https://www.metalformingmagazine.com/

‣ International Energy Agency. (n.d.). Report on Energy - Efficient Manufacturing Equipment. Retrieved from https://www.iea.org/

‣ McKinsey Global Institute. (n.d.). Study on the Impact of Robotics in Manufacturing. Retrieved from https://www.mckinsey.com/