Light-controlled uncoiler use cases

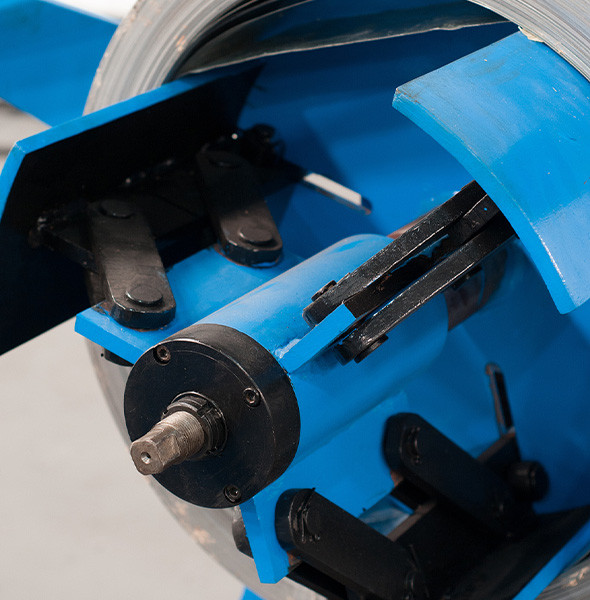

The expansion-shrinking reel is rotated by the motor-driven reducer after the uncoiler places and tightens the coil material on it. To accomplish the uncoiling goal, use the contact friction force between the coil material and the expansion and contraction reel to propel the coil material to rotate.

A specific length of material is released from the coil at the start of production by momentarily manually activating the uncoiler. After that, manually pull the released material through a variety of processing tools, including press punching machines, coil leveling machines, and coil feeder machines. Subsequently, the uncoiler is activated, with its start and stop functions dictated by the induction frame, so enabling completely automated processing and production.

Nevertheless, not all coil materials are conductive; in fact, a lot of clients manufacture and handle non-conductive raw materials, like silicon steel sheets, film materials, and certain non-metallic materials. The intermediate and time relays in the uncoiler electrical box will not jump at this time if the induction frame is still utilized for control throughout processing and production, making it impossible to manage the uncoiler's stop. This will result in constant unloading of the material coil, making automatic uncoiling impossible.

Currently, the conventional contact sensor frame control mechanism must be replaced with a through-beam photoelectric switch and a light-controlled uncoiler. During operation, the material will be automatically controlled to halt when it uncoils and sags to the point where it blocks photoelectricity. The material will start to spontaneously uncoil when it rises, so keep using it. The light control type has the advantage of being able to be sensitively adjusted without coming into contact with the material. This effectively solves the issue of material scratches and essentially achieves the automatic uncoiling and recoiling of non-conductive materials.

In addition, the light-controlled uncoiler is generally used on the 3 in 1 press feed line, which can realize automatic and precise control of this production line.

FANTY machinery Decoiler Straightener Feeder is an integrated machine that combines the advantages of a decoiler, straightener, and feeder into a single, efficient unit. It handles the unwinding of coil material, straightening it to precision, and accurately feeding it for further processing.

For any questions, you can get in touch with us directly at fanty@sz-fanty.com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://www.youtube.com/@fantydecoilerfeeder

Facebook: https://www.facebook.com/Fanty1229/

Linkedin:https://www.linkedin.com/company/fantydecoilerfeeder