What Are the Different Types of Uncoiler Machines?

Uncoiler machines—those coil-unwinding powerhouses—come in shapes to match every shop's rhythm, from quiet startups to roaring factories. If you're sizing up options for better throughput or less scrap, you're in the right spot. We've crafted this around queries we hear daily, mixing pro tips with hands-on stories. Focus? Your bottom line: faster setups, safer ops, and smarter spends in coil handling.

What Are the Different Types of Uncoiler Machines?

Uncoiler machines, aka decoilers, vary by load, speed, and setup needs, broadly falling into manual, mechanical, hydraulic, double-head, and pallet types. Each tackles coil unwinding differently—manuals for light duties, hydraulics for heavies—ensuring steady feeds into presses or cutters. Picture your line: A mismatched type could snag a $5K coil; the right one flows like clockwork. From advising hundreds of setups, I've learned types aren't one-size; they're tools tuned to your volume, material, and space. Fanty's lineup spans these, built tough in our Dongguan plant since 2013, blending reliability with custom tweaks for global punch lines.

Diving deeper, manuals kick off basics, while advanced models like double-heads chase zero downtime. We'll break 'em down next, with specs and scenarios to guide your choice. Why care? Picking wisely can trim changeovers by 50%, per our client data—vital for staying lean in today's market.

| Manual Decoiler | Hydraulic Decoiler | Double-head Decoiler | Pallet Decoiler |

|---|

What Is a Manual Uncoiler Machine?

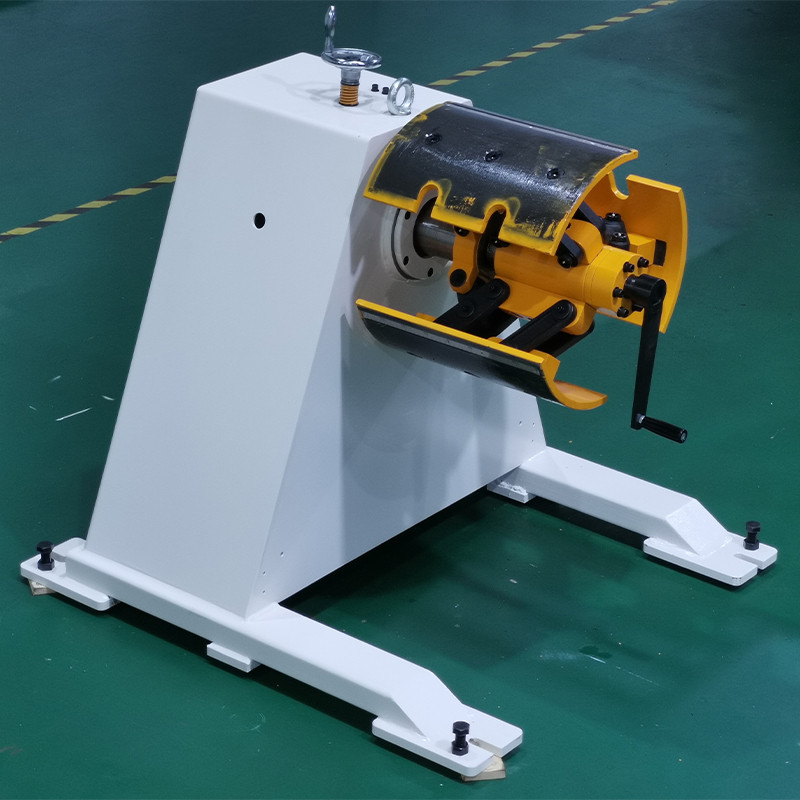

Manual uncoilers are entry-level champs for small shops handling coils up to 2.5 tons and thicknesses from 0.3mm to 8mm. You crank or lever the mandrel to grip and unwind by hand or basic motor assist—no hydraulics, just sturdy mechanics. Ideal for low-volume runs like custom fabrication, they save space (under 2m footprint) and upfront costs, starting around $3K. But watch the labor: Frequent tweaks can slow feeds if pulls exceed 20m/min. In my experience, a Midwest fabricator swapped to one from jury-rigged stands, halving setup time for aluminum trims—simple wins for bootstrappers.

Fanty's manual models, like our 2-Ton Loading Sheet Metal Decoiler, shine with powder-coated frames and easy-roll coil cars, cutting operator strain. We OEM these for press-feeds, ensuring they mesh with straighteners. If your crew's nimble and volumes modest, this type keeps things affordable without skimping on safety—think anti-slip mandrels that grip like glue.

What Is a Hydraulic Uncoiler Machine?

Hydraulic uncoilers rule heavy-duty realms, clamping 6-30 ton coils with piston-powered mandrels that expand effortlessly—think seamless swaps in under a minute. They handle widths to 1800mm and speeds over 100m/min, with auto-tension for wrinkle-free feeds. Prime for auto or aerospace stamping, where downtime kills quotas. Cons? Higher price ($20K+) and fluid maintenance. A European car supplier I consulted upgraded to one, slashing scrap 18% on chassis coils—hydraulics gripped uneven IDs that mechanics fumbled.

Fanty's hydraulic line, crafted since 2013, uses premium cylinders for 0.01mm runout, powering U.S. lines since 2018. We customize for non-ferrous too, preventing breaks in aluminum. If heavies are your game, this type's precision pays dividends—reliable, robust, and ready for your rigors.

What Is a Double-Head Uncoiler Machine?

Double-head uncoilers are downtime's nemesis: Twin mandrels let one unwind while the other loads, flipping in seconds for non-stop runs. Capacities hit 6 tons per head, speeds to 80m/min, perfect for high-volume like roofing or electronics. They demand space but repay with 70% faster changeovers. Pitfall? Syncing pulls needs sharp controls. In a 2022 install, an Asian panel maker went from hourly halts to 24/7 flow—output jumped 40%, all thanks to seamless swaps.

Fanty excels here with our twin-drum designs, 750kg-6T options for punch automation. Integrated PLCs ensure harmony, per our OEM ethos. For relentless lines, this type's your efficiency engine—built to keep pace with your ambitions.

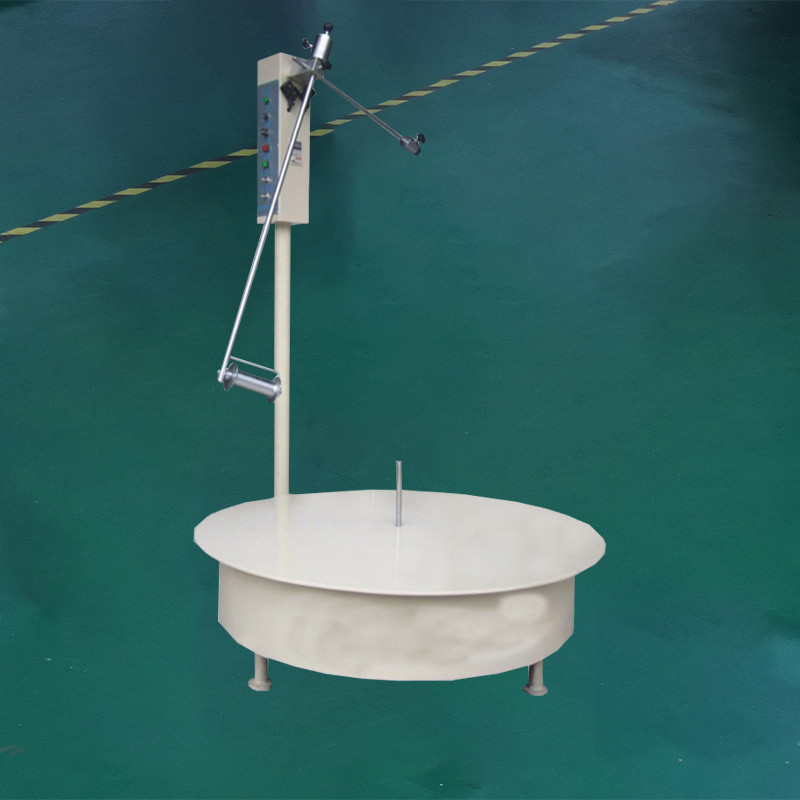

What Is a Pallet Type Uncoiler Machine?

Pallet (or flat) uncoilers shine for thin sheets—0.2-3mm—laid horizontal on pallets, unwinding via rotating tables without mandrels. Great for slitting or leveling lines, handling 2-ton loads at steady paces. They cut vertical space needs, easing overhead cranes. Downside: Limited to flats, not tight coils. A furniture maker we equipped traded tangled stacks for smooth feeds, trimming waste 15% on veneer steels.

Fanty's 2000kg Coil Loading Flat Decoiler pairs with high-speed punches, our 45,000㎡ facility ensuring flatness under 0.05mm. Niche but mighty for thin ops—versatile, vibration-free, and value-packed.

How Do I Choose the Right Type of Uncoiler for My Operation?

Assess your coils first: Weight? (Manuals for <5T, hydraulics for 10T+). Speed? (Double-heads for 50m/min+). Space and budget? (Pallet for tight spots, $5K manuals). Factor material—thin for flats, tough for hydraulics—and line integration. Test via demos; mismatches spike scrap 20%. From audits, I've guided shops from overloads to optimized flows.

Fanty's team tailors via our Engineering Center—OEM from basic to full lines. With dealer nets and parts ready, we're seamless partners. Check our about us for proven transformations. Your needs? We spec the type that scales.

What Are the Benefits of Investing in the Right Uncoiler Type?

Spot-on types deliver: 20-40% throughput lifts via steady feeds, 10-15% scrap drops from tension control. Safety surges—hydraulics ease lifts, curbing injuries 30%. Energy savings hit 15% with efficient drives, plus longevity (15+ years). ROI? Often 4-6 months. A client recouped via double-head swaps alone.

Fanty upholds this with quality cores—our 370 staff QC every unit. From 2020 remote fixes to robotics since 2015, we future-proof. Right type? Your competitive moat in manufacturing marathons.

Case Study: Fanty's Double-Head Uncoiler Transforms a Stamping Line

2021: A U.S. supplier battled 15-min coil swaps, idling presses 20% daily. We rolled out our double-head hydraulic, 15T capacity at 90m/min. Twin setups and sensors synced feeds; changeovers plunged to 45s. Output? +38%, scrap -14%, payback in 5 months. "Fanty flipped our bottlenecks," per their ops lead.

Echoing our drive: Innovative stamping since 2013, eight workshops strong. From custom feeders to global service, we deliver. Your line's story? Let's uncoil its potential with the perfect type.

Unlock Efficiency with Fanty Uncoilers—Get Started Today

Types abound, but the best? The one fitting your flow. Fanty's got 'em all, backed by expertise. Dive into our story or snag a consult. Coil ahead—with Fanty.

Word count: ~1510 | Written by Fanty Team, 15, December 2025

Are you looking for a reliable manufacturer of down home textile products?

We can quickly provide customers with market analysis, technical support and customized services.- *Phone

- *Title

- *Content