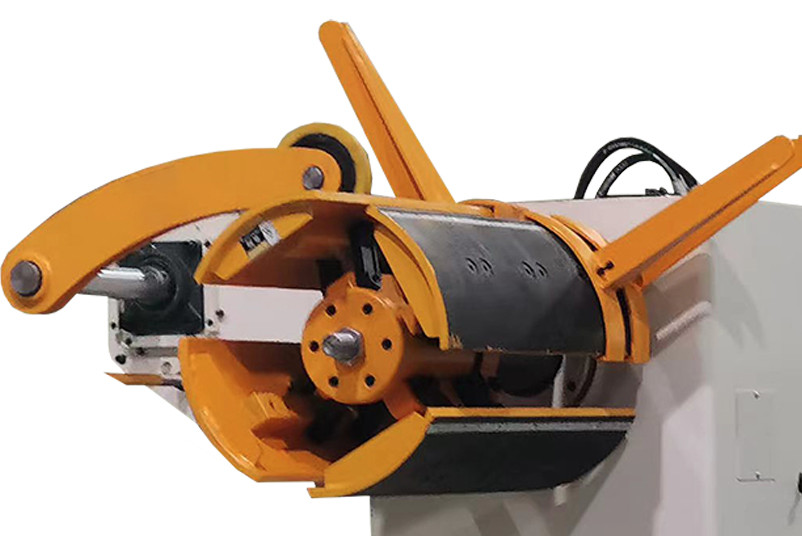

Precision Decoiler Straightener Feeder for 0.6~6.0 mm Thickness Steel Coil Handling Solution

A computerized NC control system with a more user-friendly design is used in the 3-in-1 decoiler straightener feeder. It is appropriate for feeding and straightening a variety of metal sheets; this particular machine is primarily used for materials with a thickness of 0.6 to 6.0 mm, and the stick system typically uses 7 The appropriate material can be as wide as 2000mm. In the die, there is no need for manual feeding, saving labor and enhancing safety. It is appropriate for continuous stamping processing of diverse hardware, electronics, electrical appliances, molds, and auto parts.

This model's customization options are more open-ended. Double-limit rollers can be made to order if the coil's width is narrow. Contact us for a customization inquiry.

Servo Straightener-Feeder

Operation interface

Model | DSF3-400 | DSF3-600 | DSF3-800 | DSF3-1000 | DSF3-1300 |

Stock Width(mm) | 50~400 | 50~600 | 70~800 | 70~1000 | 70~1300 |

Stock Thickness(mm) | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 |

Max.Coil Weight(kg) | 5000 | 5000 | 7000 | 7000 | 7000 |

Max.Coil O.D.(mm) | φ1400 | φ1400 | φ1400 | φ1400 | φ1400 |

Coil I.D.(mm) | φ508 | φ508 | φ508 | φ508 | φ508 |

Feed Length(mm) | 500 | 500 | 500 | 500 | 500 |

Max.Line Speed(m/min) | 16-24 | 16-24 | 16-24 | 16-24 | 16-24 |

Work Roll Number | upper4/down3 | upper4/down3 | upper4/down3 | upper4/down3 | upper4/down3 |

Feed Roll number | 1 | 1 | 1 | 1 | 1 |

Main Motor(kw) | AC5.5 | AC7.5 | AC7.5 | AC11.0 | AC11.0 |

Mandrel Expansion | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic |

Reel Motor(kw) | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 |

Power (V) | 3Phase 220V/380V/50HZ | 3Phase 220V/380V/50HZ | 3Phase 220V/380V/50HZ | 3Phase 220V/380V/50HZ | 3Phase 220V/380V/50HZ |

Operating Air(Mpa) | 0.49 | 0.49 | 0.49 | 0.49 | 0.49 |

Fanty machinery focus on the domestic market of punch press automation equipment production and sales from 2013. The field including domestic hardware industry , automotive stamping line, auto metal stamping part, saw blade production, high speed rotor and stator stamping and lamination, eyelet stamping line and so on.

We provide high quality uncoiling, leveling, feeding and punch equipment to help many local factories realize the importance of automation production, and more and more factories upgrade and improve their metal stamping line. Fanty machinery has exported machine to more than 30 countries. MORE

A: Ordinarily, it takes 30-45 days for your product to arrive once you receive an order confirmation. Furthermore, if the items are in stock, it will only take 1-2 days.

A: Because of precision decoiler straightener and feeder's high-value samples, we don't arrange the free sample.

A: Prior to manufacturing, a 30% down payment and a 70% balance are required.

A: Our Precision decoiler straightener and feeder machines are packaged in a solid wooden box

- Loading...

- *Phone

- *Title

- *Content

- *Phone

- *Title

- *Content