What Is a Disc Uncoiler Machine?

Disc uncoilers—sleek workhorses for thin coils—quietly fuel precision stamping, but picking the right one can stump even vets. If you're battling uneven feeds or space crunches in press ops, this guide's for you. Pulled from daily client chats at Fanty, it mixes specs with stories, zeroing in on your wins: Quicker setups, less waste, and lines that run like silk.

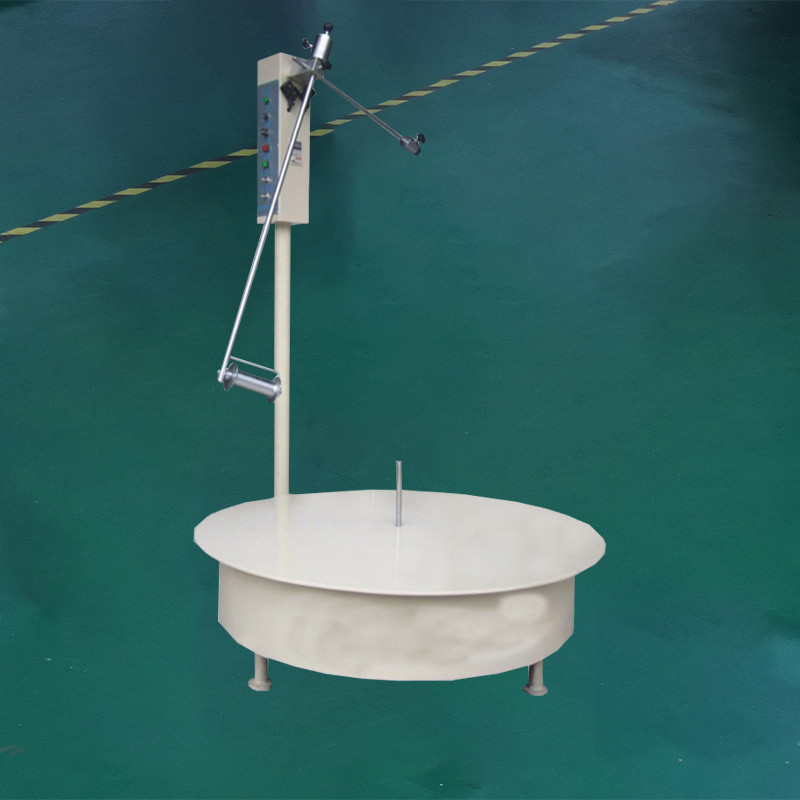

What Is a Disc Uncoiler Machine?

A disc uncoiler machine, often dubbed a flat or horizontal decoiler, is a compact unwinding device tailored for thin metal and non-metal sheets—think widths 5-120mm, thicknesses 0-1.0mm—like steel clips or aluminum terminals. Unlike vertical mandrel types, it uses a horizontal disc or pallet setup to stack and dispense multiple coils without inner-diameter limits, feeding steadily into high-speed presses at 0-30m/min. This horizontal magic prevents tangles in narrow strips, ideal for continuous stamping where downtime's the enemy. Over years fine-tuning these, I've seen them slash changeovers in electronics fabs from minutes to seconds, keeping quotas intact.

At heart, it's your line's nimble starter, inverter-controlled for smooth acceleration and precise tension via simple brakes. Fanty's flat decoilers, born from 2014 R&D pushes, handle 500-2000kg loads in our robust builds, integrating flawlessly with straighteners. We craft them for versatility—OEM-ready to fit your footprint—because in tight shops, every inch and second matters. If thin coils cramp your style, a disc uncoiler smooths the path forward.

How Does a Disc Uncoiler Machine Work?

Operation starts simple: Stack coils flat on the rotating disc or pallet—no mandrel hassles—secured by guides. An inverter motor spins it at variable speeds, uncoiling as the press pulls, while adjustable brakes maintain back-tension to avoid slack in 0.2mm sheets. Photoelectric sensors detect ends, signaling auto-stops or swaps for seamless runs. It's low-friction horizontal flow, dodging the vertical drops that snag narrow strips. In my fieldwork, tweaking inverter curves cut vibrations 40% in a terminal line, ensuring micron-flat feeds without waves.

The payoff? Non-stop feeding for hours, with easy manual or electric loading. Fanty's motorized pallet variants, since our 2017 speed boosts, hit 30m/min reliably, syncing via PLC to feeders. Built in our eight Dongguan workshops with HRC58 rollers, they thrive in dusty floors—durable, intuitive, and downtime-proof. For users juggling batches, this workhorse delivers consistency that scales with your output.

What Are the Key Components of a Disc Uncoiler Machine?

Essentials include the horizontal disc or pallet base—steel-framed for 1000kg stacks—paired with an inverter drive (1-3kW) for 0-30m/min control. Tension arms or pneumatic brakes fine-tune pull, while edge guides align 5-120mm widths. Add photoelectric eyes for auto-alerts and a compact frame (under 2m wide) with casters for mobility. Skip robust bearings? Wobbles wreck precision. From audits, underrated are the anti-static rollers—ours prevent dust cling in non-metals.

Fanty amps it with user-friendly panels and overload sensors, QC'd by our 80+ R&D crew for <0.05mm flatness. Models like our 1000kg electric horizontal shine in integrations, cutting parts count. Tailored for thin ops, these components aren't add-ons—they're your reliability core, forged for years of grit-free service.

What Are the Advantages of a Disc Uncoiler Machine?

Disc uncoilers excel in compactness—halving space vs. verticals—while stacking multiples boosts uptime 50% by dodging ID constraints. High-speed inverter control trims scrap 10-15% on thin gauges, and horizontal feeds reduce operator strain, aligning with safety regs. Cost? Entry at $5K, ROI in 4 months for press lines. Versus heavies, they're lighter on maintenance—no hydraulics to leak. I've consulted swaps where they hiked throughput 25% in eyelet production, sans extra floor digs.

Versatility seals it: Metals to plastics, 0.1-1.0mm thick. Fanty’s designs, with 2015 pallet innovations, add auto-electric loading for 20% faster setups. Our 370-team QC ensures vibration-free runs, perfect for lean factories chasing green efficiency. If space or speed bites, disc uncoilers bite back—smart, scalable, and savvy.

What Are the Main Applications of Disc Uncoiler Machines?

In automotive, they dispense narrow steel for clips and brackets, feeding 1000spm presses without hitches. Aerospace leans on them for titanium foils in fasteners, where flat feeds avert defects. Appliance lines unwind aluminum for buttons, high-speed ensuring dent-free shells. Electronics? Copper strips for terminals, stacked coils fueling PCB assembly. Broader: Hardware eyelets or medical stents, anywhere thin precision rules.

Demand? Batch flexibility without pauses. Fanty's high-speed models powered a 2020 U.S. terminal run, lifting yields 30%. Our integrations with straightener-feeders exemplify seamless flow—compact for retrofits. From auto to aero, disc uncoilers adapt, turning coil chaos into crafted wins tailored to your sector.

How Do I Maintain a Disc Uncoiler Machine?

Daily: Wipe disc of shavings, check inverter belts for wear—tighten as needed. Weekly: Lubricate bearings with light oil, test tension brakes for even grip on sample coils. Monthly: Calibrate sensors via display, inspect guides for burrs that snag 0.3mm sheets. Annually: Full alignment, motor audit. Tools? Basics like torque wrenches; our guides simplify. Neglect invites 20% more stops—proactive nips that in bud, saving $2K yearly per my client logs.

Fanty eases it with modular parts and remote diagnostics in smart units, slashing checks 40%. Post-2022 upgrades, our service nets deliver spares in days. Maintenance? Less grind, more grindstone—keeping your disc spinning true for the long haul.

How Do I Choose the Right Disc Uncoiler for My Needs?

Gauge your coils: Width (20-100mm?), load (500-2000kg?), speed (10-30m/min?). Space? Under 1.5m wide fits most. Electric or manual? Auto for 24/7, basic for bursts. Budget: $4K-$12K, factor integration costs. Trial a demo—mismatches spike waste 15%. Tip: Future-proof with modular add-ons like stackers. From specs reviews, overkill burdens; right-fit frees flow.

Fanty's Engineering Center customizes—OEM from your blueprint, with dealer support galore. See our about us for global success stories. Your puzzle? We piece the perfect disc.

Case Study: Fanty Disc Uncoiler Speeds Up an Electronics Stamping Line

2021: A California electronics firm wrestled with tangled 0.5mm copper coils on vertical uncoilers, halting presses 25% daily—$30K losses monthly. We deployed our 1000kg motorized pallet disc uncoiler: Horizontal stacking for five coils, 25m/min feeds synced to feeders. Inverter precision ironed tensions; swaps dropped to 30 seconds. Throughput? +28%, scrap -11%, payback in five months. "Fanty's disc turned our coil curse into a conveyor dream," per their lead tech.

Mirroring our ethos: Innovation from 2013, resilient through 2020s. Eight workshops, 370 hands—Fanty crafts turnkey triumphs. Your line's lag? Let's disc it away with tailored torque.

Streamline Your Stamping with Fanty Disc Uncoilers—Reach Out Today

Disc uncoilers? Gateways to glitch-free thin-coil worlds. Fanty's got the edge, from roots to revolutions. Unpack our story or grab a consult. Flatten your future—with Fanty.

Word count: ~1518 | Written by Fanty Team, 16,December 2025

Are you looking for a reliable manufacturer of down home textile products?

We can quickly provide customers with market analysis, technical support and customized services.- *Phone

- *Title

- *Content