Mechanical Press Transfer Systems

- Uses cam-driven mechanisms for high-speed, synchronized transfer.

- Ideal for progressive die stamping and mass production.

- Reliable and cost-effective with minimal maintenance.

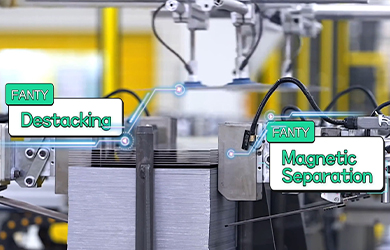

Sheets or blanks are fed into the system via a coil feeder or destacker.

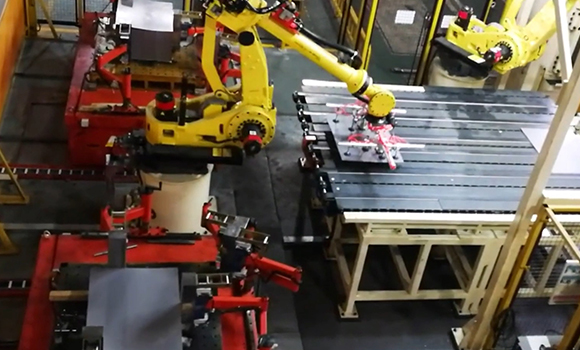

The transfer unit moves the workpiece through different die stations using mechanical linkages, servo actuators, or robotic arms.

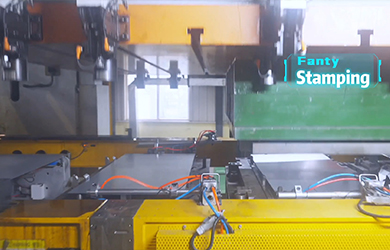

The transfer system operates in perfect sync with the press, ensuring each workpiece is accurately positioned.

Finished parts are automatically ejected and stacked for further processing.

Increases production throughput with synchronized motion control.

Ensures accurate workpiece positioning across all die stations.

Compatible with various press types and automation lines.

Eliminates manual intervention, reducing workplace hazards.

Improves material utilization and process efficiency.

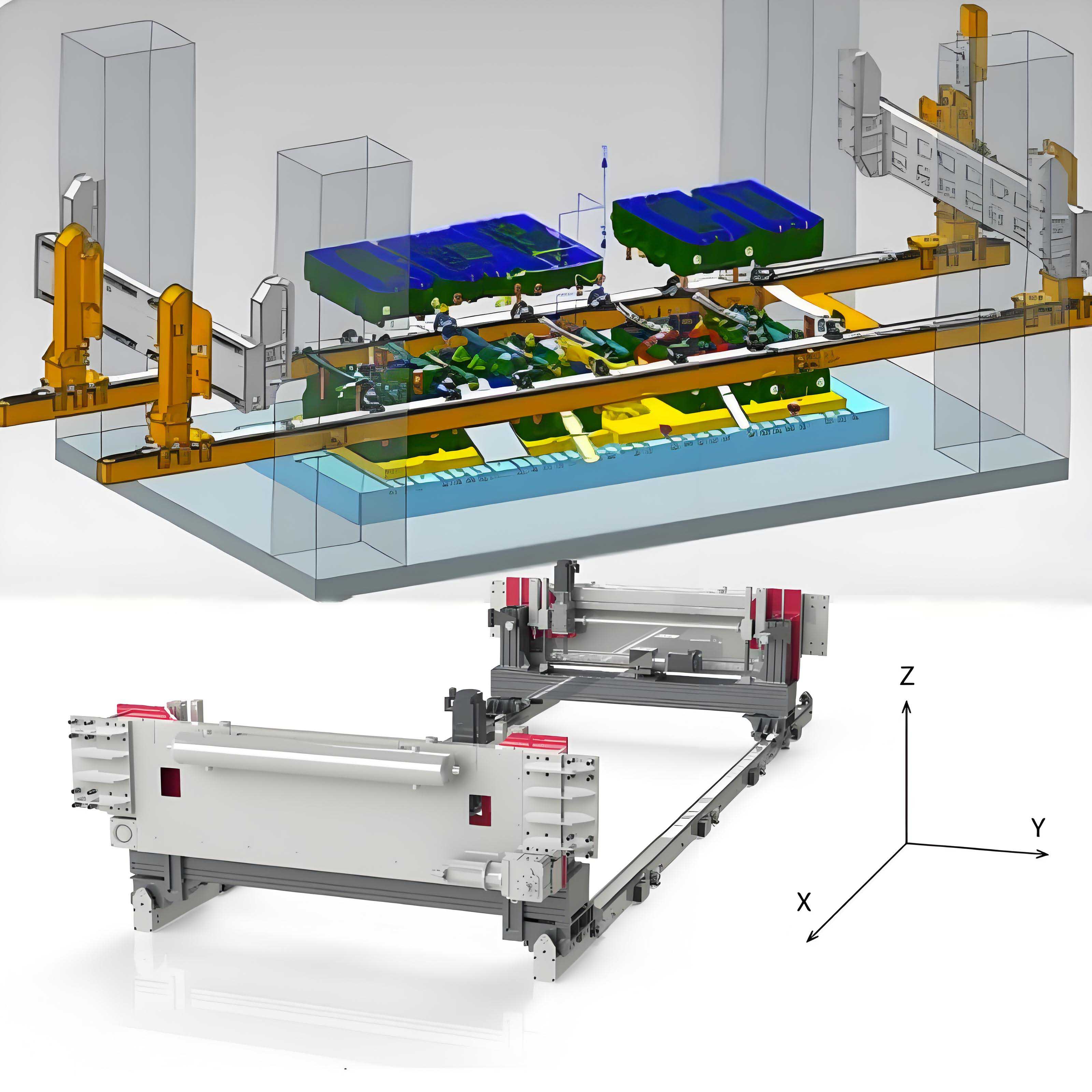

Horizontal movement of the transfer system. It is usually along the width of the punching press bed.

The vertical movement of the transfer system. It is usually along the height of the punching press bed.

It is usually in and out of the punching press bed, towards or away from the operator or other equipments.

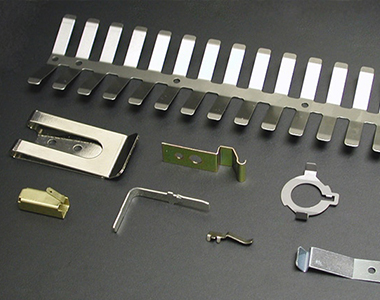

* Transferring metal blanks for stamping car body panels

* Moving engines, chassis, and parts along assembly lines

* Feeding metal sheets or coils into press machines

* Moving stamped parts to subsequent processes like welding or painting

* Transfer of parts like panels, frames, and casings for assembly

* Automated handling of small components

* Feeding metal sheets or coils into press machines

* Delicate handling and processing of components.

We design solutions tailored to your production needs.

Our systems integrate AI-driven controls and IoT monitoring.

Trusted by global manufacturers for reliability and efficiency.

Customized service, providing production improvement suggestions.

From system design to installation and after-sales service.

Fanty can provide you a customized stamping automation line.

Decoiler machine, nc servo feeder, decoiler straightener, decoiler straightener feeder, punch press, transfer...

We are also acting as a distributor of Metal Stamping Automation Equipments & Transfer Equipments on the market !