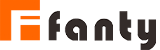

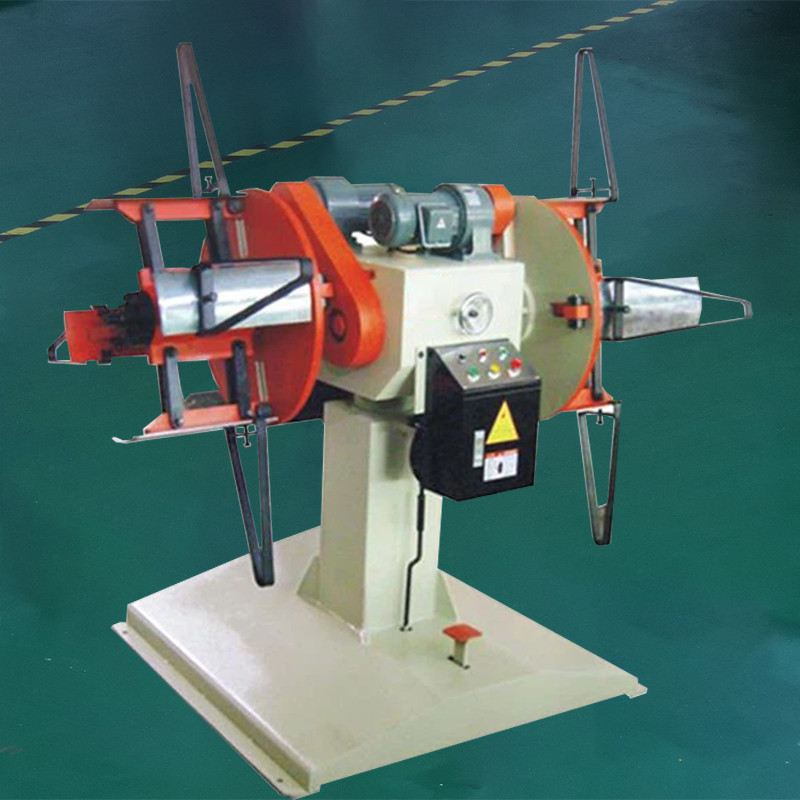

Double Head Decoiler

In the dynamic landscape of industrial machinery, the Double Head Decoiler emerges as a sophisticated solution, revolutionizing material handling in precision stamping lines. This article delves into the core characteristics of Double Head Decoilers, defining their role, highlighting key features, applications in stamping lines, and addressing the critical concerns that captivate the attention of discerning industry professionals.

What is a Double Head Decoiler?

A Double Head Decoiler is an advanced material handling machine equipped with two decoiling heads, operating in tandem to enhance efficiency in the unwinding and feeding of metal coils. This innovative design ensures a continuous and seamless supply of material, a critical factor in industries demanding high-speed and precision stamping operations.

Key Features of Double Head Decoilers

Dual Decoiling Heads: The standout feature is the incorporation of two decoiling heads, allowing for simultaneous unwinding of two coils. This dual functionality significantly improves material handling speed.

Individual Tension Control: Each decoiling head is equipped with individual tension control mechanisms, providing precise and independent control over each coil's unwinding process.

Adaptive Coil Handling: Double Head Decoilers exhibit adaptability, seamlessly handling a variety of coil specifications, materials, and thicknesses, offering versatility in stamping line applications.

Space-Efficient Design: Despite its dual functionality, these decoilers are engineered with a space-efficient design, optimizing floor space in industrial settings.

Applications in Stamping Lines

Double Head Decoilers find strategic applications in high-volume precision stamping lines, particularly in industries such as automotive manufacturing, appliance production, and electronics. The simultaneous unwinding capability proves invaluable in scenarios where efficiency and speed are paramount.

Customer Concerns and Solutions

High-Speed Performance: Clients in high-volume production environments prioritize speed. Double Head Decoilers address this concern by simultaneously unwinding two coils, significantly increasing material handling speed and overall production efficiency.

Individual Tension Control: Precision in material feeding is critical. The individual tension control mechanisms on each decoiling head provide clients with precise control, ensuring uniform material feeding and preventing coil distortion.

Adaptability and Versatility: Industries with diverse material requirements seek adaptable solutions. Double Head Decoilers are designed to handle various coil specifications, materials, and thicknesses, offering versatility in stamping line applications.

Space Efficiency: Efficient use of floor space is a common concern. Our Double Head Decoilers feature a space-efficient design, accommodating dual functionality without compromising the optimization of industrial floor space.

Conclusion

In conclusion, the Double Head Decoiler emerges as a game-changer in the realm of precision stamping, blending efficiency with adaptability. For industries seeking to elevate their high-speed stamping operations, investing in Double Head Decoilers is a strategic move towards enhanced productivity and operational excellence. Transform your stamping line with the dual power and precision of our cutting-edge Double Head Decoiler technology.

1 products found

Working with S-type straightening machine, gear feeder and high speed punch press machine for high speed stamping line.

Categories

subscription

Please send your message to us

Contact FANTY today for efficient solutions that optimize your manufacturing processes. Our expertly designed equipment ensures safe and precision steel coil handling, enhancing your production efficiency. Get in touch with us now to elevate your manufacturing capabilities.

- Tel

- *Title

- *Content