ATS integrates a network of conveyor systems to transport materials, components, and finished parts within the production line. These conveyors are the backbone of the system, ensuring a continuous workflow.

Automatic Transfer System (ATS)

What is an Automatic Transfer System (ATS)?

INTRODUCTIONAn Automatic Transfer System (ATS) is an advanced automation solution designed to facilitate seamless material handling, part assembly, and quality control in the manufacturing of mechanical equipment. It empowers production lines with precision and efficiency by automating complex tasks and minimizing human intervention. Normally the Key Components of an ATS including:

2 Robotics and Automation

Robotic arms, automated pick-and-place systems, and CNC machines play a pivotal role in ATS. They handle tasks such as part loading, assembly, welding, and inspection with unmatched accuracy.

3 Control Software

Advanced control software governs the operation of ATS, orchestrating the movement of materials and machines, and enabling real-time monitoring and adjustments

What automatic transfer system that we are providing

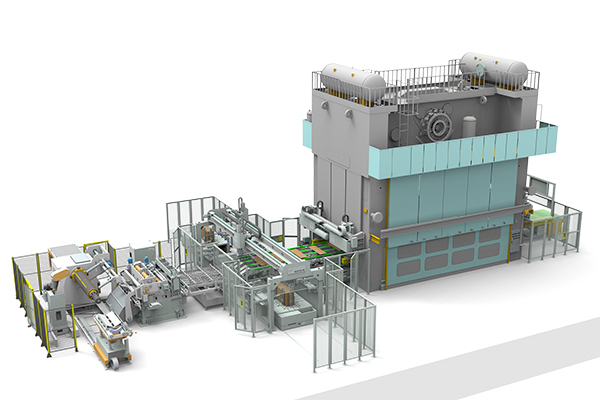

FANTY'S Multi-Automatic Transfer SystemAt Fanty, we are at the forefront of developing a cutting-edge transfer automated stamping production line. Our dedicated team of experts is tirelessly working to integrate state-of-the-art robotic technology into the stamping process, revolutionizing productivity and efficiency. By harnessing the power of transfer , we aim to automate repetitive tasks, enhance precision, and improve overall production speed. Our commitment to innovation and continuous improvement drives us to push the boundaries of automation, ensuring that our customers benefit from the latest advancements in the industry. With Fanty's transfer automated stamping production line, you can expect increased productivity, reduced labor costs, and superior quality products. Join us on this exciting journey towards a future where automation transforms the manufacturing landscape.

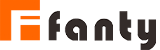

1 Swing arm stamping transfer

The swing arm stamping transfer combines the flexibility of joint robots with the stability of link transfer, easily meeting diverse feeding and mold process requirements in stamping production.

- Flexible Integration: Connect various presses, regardless of tonnage, punch height, or multiple combinations, saving customers 50-60% on equipment investment.

- Versatile Mold Compatibility: Our solution easily adjusts to non-standard molds, enabling quick position selection in 3 minutes.

- Flexible Production Setup: Easily adjust and switch production wiring methods according to specific needs through our user-friendly interface.

- Operability: Adopting open programmable technology, it can store multiple product information, has strong interchangeability, and can be set once for long-term use.

- Efficiency: 10-15 times/minute

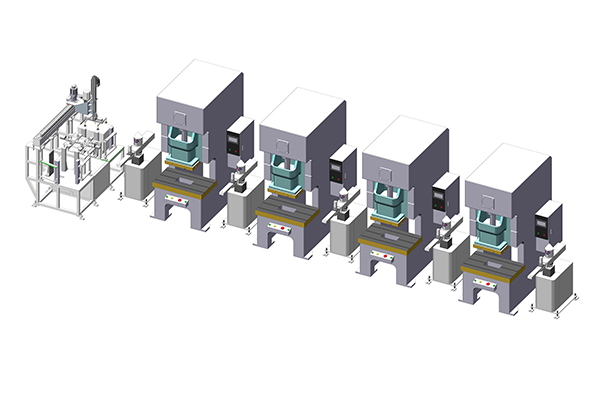

2 Transfer System Tandem Line

Tandem Line is appropriate for configurations of four-point, multi-station presses weighing between 1000 and 3200 tons; the production beat is primarily between 15 and 30 spm; and the press table is longer than 6000mm.

- Adopts well-known mainstream brands like KUKA in Germany, ABB in Switzerland, and Fanuc in Japan.

- Use a German Cognex visual alignment system and a German Roland detector to ensure that the entire line is being produced safely.

- Can have integrated oiling & cleaning features

- can satisfy one mold and two pieces of the typical production requirements.

- Free up manpower and boost production effectiveness

3 Independent Stamping Transfer

Independent Stamping Transfer is a type of robotic arm applied to punching machines, mainly replacing manual manual work for automatic loading, unloading, picking, and feeding. It can improve the level of automation in the production process, and the use of robotic arms is conducive to improving the automation level of material transmission, workpiece loading and unloading, independent stamping robotic arm tool replacement, and machine assembly

- The equipment adopts Mitsubishi high-performance PLC control system to meet the high efficiency operation requirements of the equipment

- Adopting a dedicated robot controller and servo system, the repetitive positioning accuracy is higher, the speed is faster, the algorithm is precise, and the motion is smooth

- The material can be grabbed using various methods such as vacuum suction cups, electromagnets, vacuum grippers, etc

- The production line can be equipped with additional auxiliary equipment such as Feeder, sheet material accumulation rack etc. to achieve connected production

- Suitable for automated production of automotive covers & TV backboards

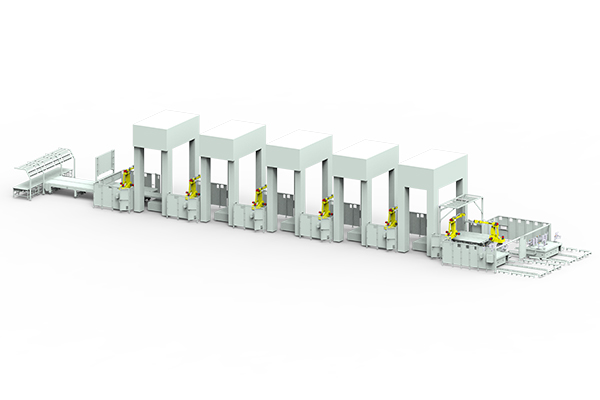

4 Multi-station Transfer Stamping Line

Uncoiler cum straightener/Uncoiler straightener feeder + Dua-station destacking machine+Mult-station Transfer production line

- The base material can be coil material (progressive die/multi station) or sheet material (multi station), with multiple modes, high flexibility, and improved press usage rate

- Servo motor driven

- Equipped with a conveyor belt at the end of the line and a comprehensive safety protection system

- Suitable for automated stamping production of small and medium-sized parts

Increased Efficiency

01Improve production efficiency by reducing manual labor & increasing process automation.

Enhanced Precision

02Perform tasks with precision, minimizing errors and improving product quality.

Consistent Performance

03Perform tasks with unwavering accuracy, eliminating variations found in human labor.

Higher Production Speed

04Rapid & repetitive movements enable higher production speeds, resulting in greater output and shorter cycles.

Improved Safety

05Handle hazardous and repetitive tasks, reducing risks and enhancing workplace safety.

Cost Reduction

06Reduces labor costs, minimizes waste, and optimizes production processes for savings.

Flexibility & Adaptability

07Allows for easy reprogramming & reconfiguration to quickly adapt to changing production needs and product variations.

Data Collection and Analysis

08Enable real-time monitoring and analysis of production metrics for continuous process improvement.

Application of Automatic Transfer System

Automatic Transfer System for Automotive Parts Stamping Line

The automatic transfer system used in the Automotive Parts Stamping Line can increase production effectiveness, guarantee product quality, increase worker labor productivity, assure personal safety, and decrease risk costs for businesses. Our cutting-edge Automatic Transfer System revolutionizes the efficiency of automotive parts stamping lines. Designed to seamlessly integrate within the production process, this system ensures smooth and precise transfer of components between various stages. With advanced automation and intelligent control, it optimizes workflow, reduces downtime, and enhances overall productivity. From loading to unloading, this innovative solution guarantees consistent and reliable movement of parts, meeting the demands of high-volume production while maintaining top-tier quality.

Automatic Stamping Production Line Customized for You

Our experienced team understands the unique requirements of your manufacturing processes and can design and tailor a production line that precisely matches your needs. From initial concept to final implementation, we work closely with you to ensure that the automated stamping line is optimized for efficiency, productivity, and quality. With our expertise in automation technology and comprehensive range of equipment, we can create a fully integrated and efficient production line that maximizes your productivity, reduces costs, and delivers exceptional results.

Trust Fanty to provide you with a customized automatic stamping production line that meets your exact specifications and drives your success in the manufacturing industry.

Customized Automatic Stamping Production Line Including

- Two arms flexible production line

- Multi-station composite production line for coil material

- Progressive die production line

- Uncoiling and cutting production line

- High strength steel progressive production line

- Uncoiling and cutting production line

other equipments shall be involved in A complete Automatic transfer system

equipmentThe advanced automatic transfer system features by FANTY providing ensures high performance and productivity. As a result, in addition to the electronic transfers itself, the automation process also involves other electronic and mechanical parts and accessories, such as uncoiler/decoiler, feeders, press, or robots, as well as simulation or control software. All of these components' optimized designs ensure a flawlessly synchronized process that raises the system's productivity and the effectiveness of the entire installation.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content