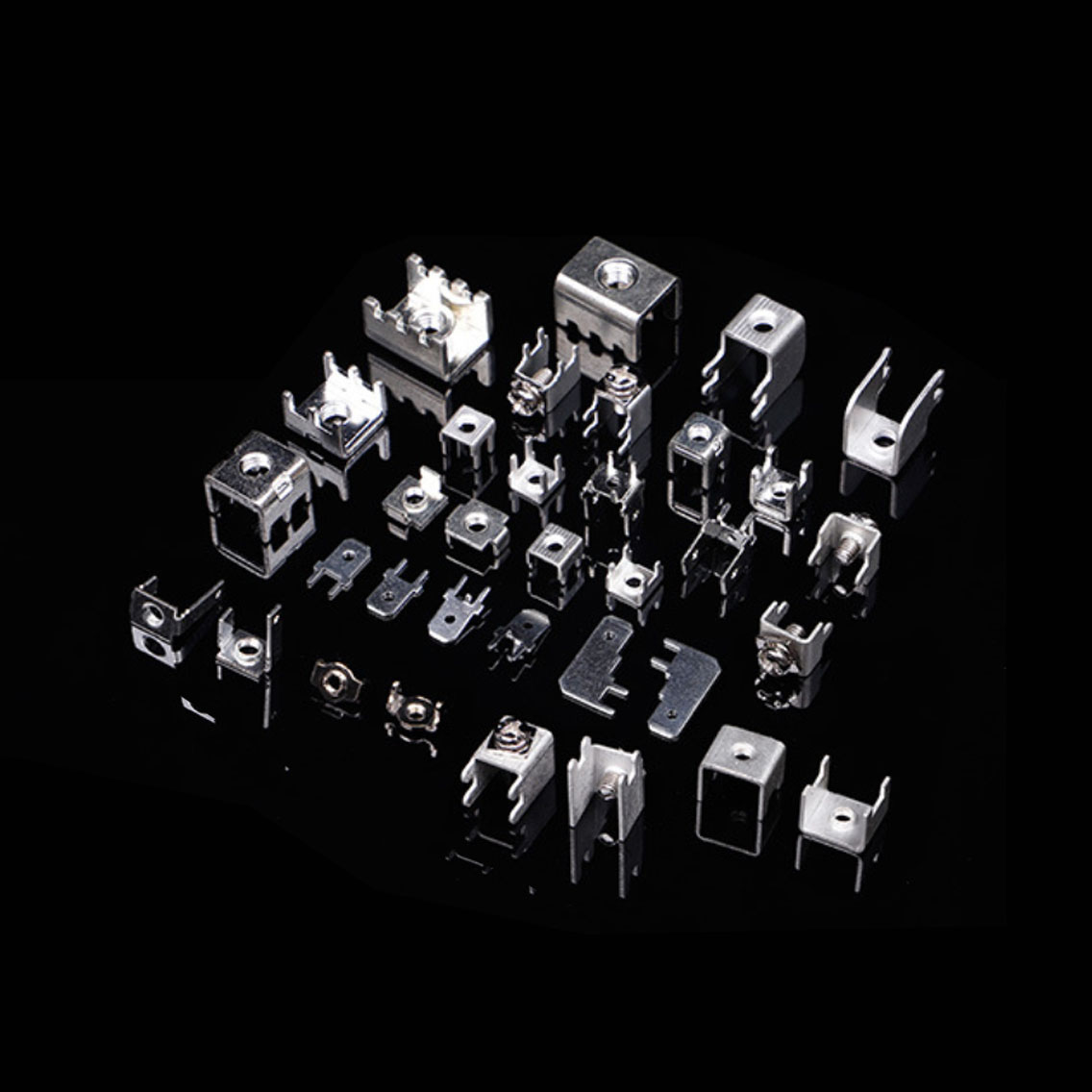

Creating a precision mold of the highest caliber is an investment in your business. The price of a Progressive sheet metal stamping is affected by a number of factors:

1 Mold Design

Our design engineers and fitters have an average industry experience of over 10 years. Skilled and exquisite mold matching experience.

- Expert Mold Design: Our team of experienced designers excels in creating highly precise and efficient mold designs that meet your specific requirements.

- Advanced CAD/CAM Software: Leveraging cutting-edge CAD/CAM software, we utilize the latest design tools and techniques to develop intricate 3D mold models and optimize the manufacturing process.

- Collaborative Approach: We actively involve you in the mold design process, seeking your input and feedback to ensure the final design aligns perfectly with your expectations and production needs.

- Prototyping and Iteration: Through prototyping and iterative design cycles, we validate and refine the mold design, addressing any potential issues and fine-tuning the final product. 4-8 weeks molding making

- Quality Assurance: Our commitment to quality is paramount. We conduct thorough inspections and testing to ensure that every mold design meets the highest standards of precision, functionality, and durability.