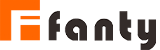

Combination Decoiler Straightener Feeder for 0.5~4.5 mm Thickness Steel Coil Handling Solution

Combination Decoiler Straightener Feeder for 0.5~4.5 mm Thickness Steel Coil Handling Solution

| Categories | Decoiler Straightener Feeder |

|---|---|

| Brand | FANTY Steel Coil Handling Equipment Manufacturer |

| Model | DSF2 Series Combination Decoiler Straightener Feeder |

| Color | Standard white (other colors are available) |

| Payment | 30% T/T as deposit, rest against shipping |

| Customized Service | Yes |

| Certificate | ISO, CE |

| FOB port | FOB Shenzhen |

| Terms of Payment | L/C, Western Union |

| Update Time | Apr 28,2024 |

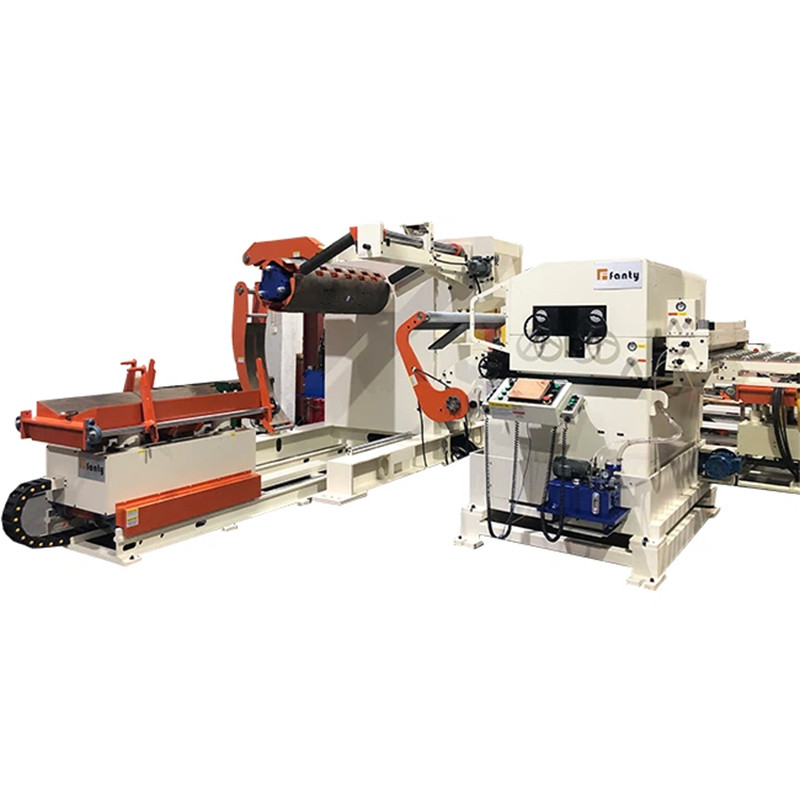

The DSF2 3-in-1 decoiler straightener feeder has a 3-in-1 design and is made up of a coil feeder, an automatic material rack (decoiler), and an automatic material straightener machine. It can be utilized for continuous die feeding with punching machines as well as continuous shearing with regular shearing machines. These machines are typically used to straighten materials that range in thickness from 0.5 to 4.5 mm. The stick method typically uses 7 or 9 sticks, and the greatest width of the material employed is 1000mm. In the hardware and automotive components sectors, it is commonly used. Currently, 600mm models can be customized, and 85SPM is the highest feeding speed possible.

Model | DSF2-400 | DSF2-600 | DSF2-800 | DSF2-1000 |

Stock Width(mm) | 50~400 | 50~600 | 70~800 | 70~1000 |

Stock Thickness(mm) | 0.5~4.5 | 0.5~4.5 | 0.5~4.5 | 0.5~4.5 |

Max.Coil Weight(kg) | 5000 | 5000 | 7000 | 7000 |

Max.Coil O.D.(mm) | φ1400 | φ1400 | φ1400 | φ1400 |

Coil I.D.(mm) | φ508 | φ508 | φ508 | φ508 |

Feed Length(mm) | 500 | 500 | 500 | 500 |

Max.Line Speed(m/min) | 16-24 | 16-24 | 16-24 | 16-24 |

Work Roll Number | upper4/down3 | upper4/down3 | upper4/down3 | upper4/down3 |

Feed Roll number | 1 | 1 | 1 | 1 |

Main Motor(kw) | AC4.4 | AC4.4 | AC5.5 | AC7.5 |

Mandrel Expansion | hydraulic | hydraulic | hydraulic | hydraulic |

Reel Motor(kw) | 2.2 | 2.2 | 3.7 | 3.7 |

Power (V) | 3Phase 220V/380V/50HZ | 3Phase 220V/380V/50HZ | 3Phase 220V/380V/50HZ | 3Phase 220V/380V/50HZ |

Operating Air(Mpa) | 0.49 | 0.49 | 0.49 | 0.49 |

Servo Straightener-Feeder

Operation interface

Fanty machinery focus on the domestic market of punch press automation equipment production and sales from 2013. The field including domestic hardware industry , automotive stamping line, auto metal stamping part, saw blade production, high speed rotor and stator stamping and lamination, eyelet stamping line and so on.

We provide high quality uncoiling, leveling, feeding and punch equipment to help many local factories realize the importance of automation production, and more and more factories upgrade and improve their metal stamping line. Fanty machinery has exported machine to more than 30 countries. MORE

A: First, our research and development staff is highly technical;

Second, we can design and plan the entire plant to execute the turnkey project;

Third, our attitude is that social responsibility begins with quality;

Fourth, our products have gained market traction and have found applications in the hardware, home appliance, and major automotive OEMs;

Fifth, We have a highly successful after-sales crew, and we receive positive client feedback.

A: YES, our decoiler straightener feeder machines are certificated with CE

A: We will arrange combination decoiler straightener feeder equipment shipment for you at a FOB or CIF price, dear esteemed customers. To obtain an EXW price, clients must schedule their own shipments or use their agents to do so.

A: Container for plastic film that is weather-resistant and has foam corner guards

for delivery, a solid wooden box

Make the most space possible for container loading.

- Loading...

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content