What Main Components and Functions Do Decoiler Have?

The Fundamentals of Decoilers: Components and Functions

Decoilers are integral components in various manufacturing industries, facilitating the unwinding of coils with precision and efficiency. Understanding the key components and functions of decoilers is paramount for optimizing production processes. In this article, we delve into the fundamental aspects of decoilers, shedding light on their intricate mechanisms and operational significance.

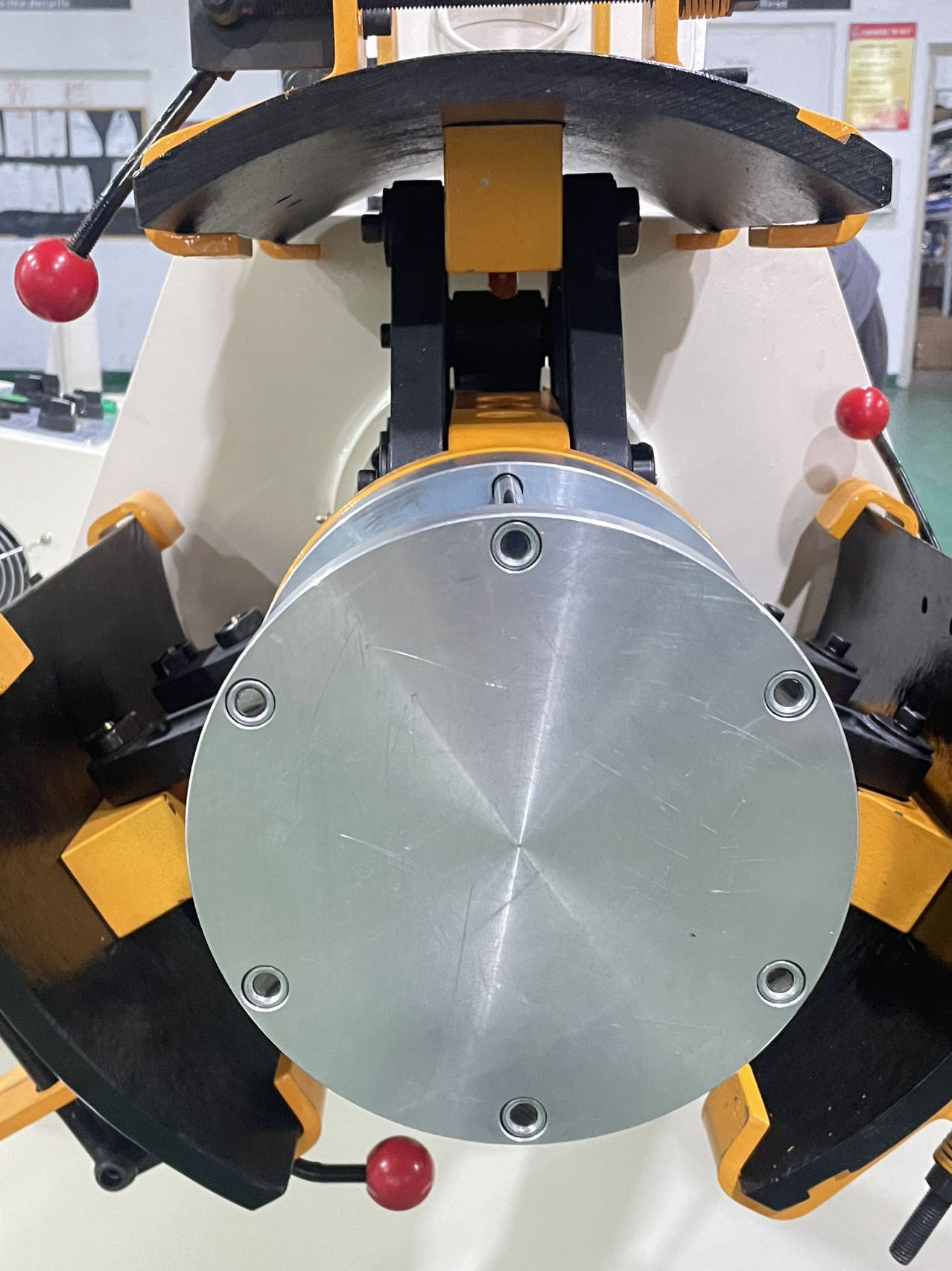

Mandrel of Decoiler

Decoilers consist of several essential components, each contributing to their overall functionality. At the core of a decoiler lies the mandrel, a cylindrical shaft around which the coil is wound. The mandrel serves as the primary support structure, providing stability and alignment during the unwinding process. Depending on the application, decoilers may feature adjustable mandrels to accommodate coils of different sizes and materials.

Press Arm

Accompanying the mandrel is the press arm, responsible for regulating the speed and tension of the unwinding material. This mechanism typically comprises rollers or grippers that exert controlled pressure on the coil, ensuring smooth and consistent material feed. Precision in tension control is crucial to prevent material slippage or distortion, thereby maintaining product quality and process efficiency.

Accompanying the mandrel is the feeding mechanism, responsible for regulating the speed and tension of the unwinding material. This mechanism typically comprises rollers or grippers that exert controlled pressure on the coil, ensuring smooth and consistent material feed. Precision in tension control is crucial to prevent material slippage or distortion, thereby maintaining product quality and process efficiency.

Decoilers also incorporate safety features to mitigate operational risks and ensure a secure working environment. Emergency stop buttons, overload protection systems, and interlocking guards are common safety measures implemented in decoiler designs. By prioritizing operator safety, manufacturers can minimize the likelihood of accidents and enhance overall workplace productivity.

In summary, decoilers play a pivotal role in modern manufacturing operations, facilitating the seamless unwinding of coils for subsequent processing. By understanding the fundamental components and functions of decoilers, manufacturers can optimize production efficiency and uphold stringent quality standards. More decoilers knowledge, pls visit us: https://www.decoilerfeeder.com/products2128912/Decoiler.htm